Another day of the PRINTING United Expo is behind us, and we’ve absorbed another day’s worth of show floor activities, educational sessions, and more.

While yesterday we focused on things like new tech in the apparel decoration world, UV printing, colorful promos, and more, today we’re looking at products that take decoration that quite literally pops right off the product.

3-D Features with Ink on Drinkware

We stopped by the LSINC booth, where chief commercial officer Jim Lambert walked us through a demonstration of their glassware decoration process. We were sucked in by the robotic arms grabbing four tapered pint glasses at a time, but stuck around when we learned that the printing process allowed for 3-D imprints that looked like the glass was molded. But, it was all ink, making it easy and more affordable to create unique drinkware pieces that take branding beyond the label.

“This one’s good for cylinders and tapers, and this is four independent print tunnels,” Lambert says of the machine in front of us. “We have a single version, which is one print tunnel, which is what a lot of people are looking at that are just getting into this market. I’m a big fan of the movie ‘What About Bob?’ you know, baby steps on the bus when they’re trying to get him on the bus. If you’re just starting that’s the one we try to direct people to. The same kind of print can go on tapered or cylindrical stuff, and it’s just one print tunnel instead of four.”

When asked about what makes this decoration so attractive to end-users, distributors and suppliers alike, he says it’s the ability to create what looks like molded glass through ink, saving money and time by removing steps in the process.

“We’ll call it embellishment, where you could get some really cool effects that you normally wouldn’t see,” Lambert says. “That’s actually ink. When guys are talking about special molds for glass, you’re talking a ton of money, and the time to create the mode and the time to make the glass. What we’re saying is, buy the glass, buy the plain glass, and then embellish with digital printing. So you could do really some cool, cool effects. And with this, feel how the name is kind of engraved. That’s all ink. That’s all digitally printed.”

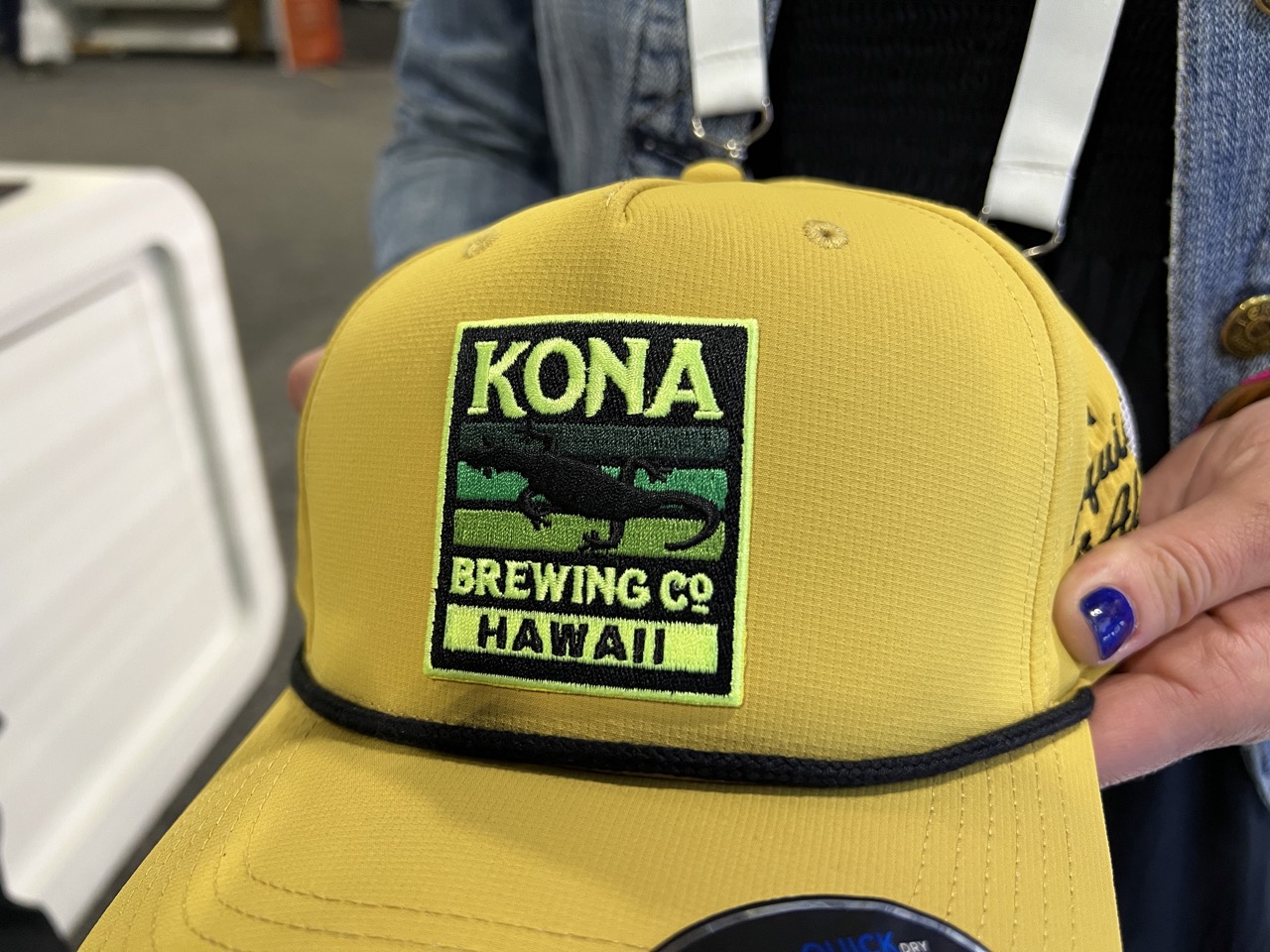

Heat Seal and Patch Decoration

Grace Schettler, vice president of sales for Cap America, walked us through how heat transfer caps have changed even within the last few years. In the past, they were a much flimsier alternative to decoration techniques like embroidery or sewn on patches. While embroidery, she says, is still probably the most popular method and the fastest for them to do, sewn on patches and heat transfer aren’t far behind, and heat transfer specifically offers some good options for distributors and end-users.

“A heat seal looks very similar to a sewn-on [patch],” she says. “A heat seal has gone a very long way as long as the stickiness and adhesive behind it. The adhesive, you can’t pick it off. I would say two years ago, you could get your finger under it. And they’ve done a really good job, the patch manufacturers, of making sure they stay.”

An embroidered patch allows for detail that an embroidered logo might not allow. Think about things like jagged little state lines on a logo, or something similarly intricate. Just embroidering that might not yield the result you or your end-user want. An embroidered patch takes a similar amount of time, looks like an embroidered logo, but will look more like your client envisioned.

She also said that rubber patches have been super popular for Cap America.

“You get all of the detail of a patch, like you can get that extremely detailed, you can PMS match colors on the rubber,” she says.

Simply adding a patch, even a small one, immediately transforms a product. For name-brand appeal, you could take an item like a bag or shoe, and apply a patch to create a co-branded item that has the power of two logos or brand messages.

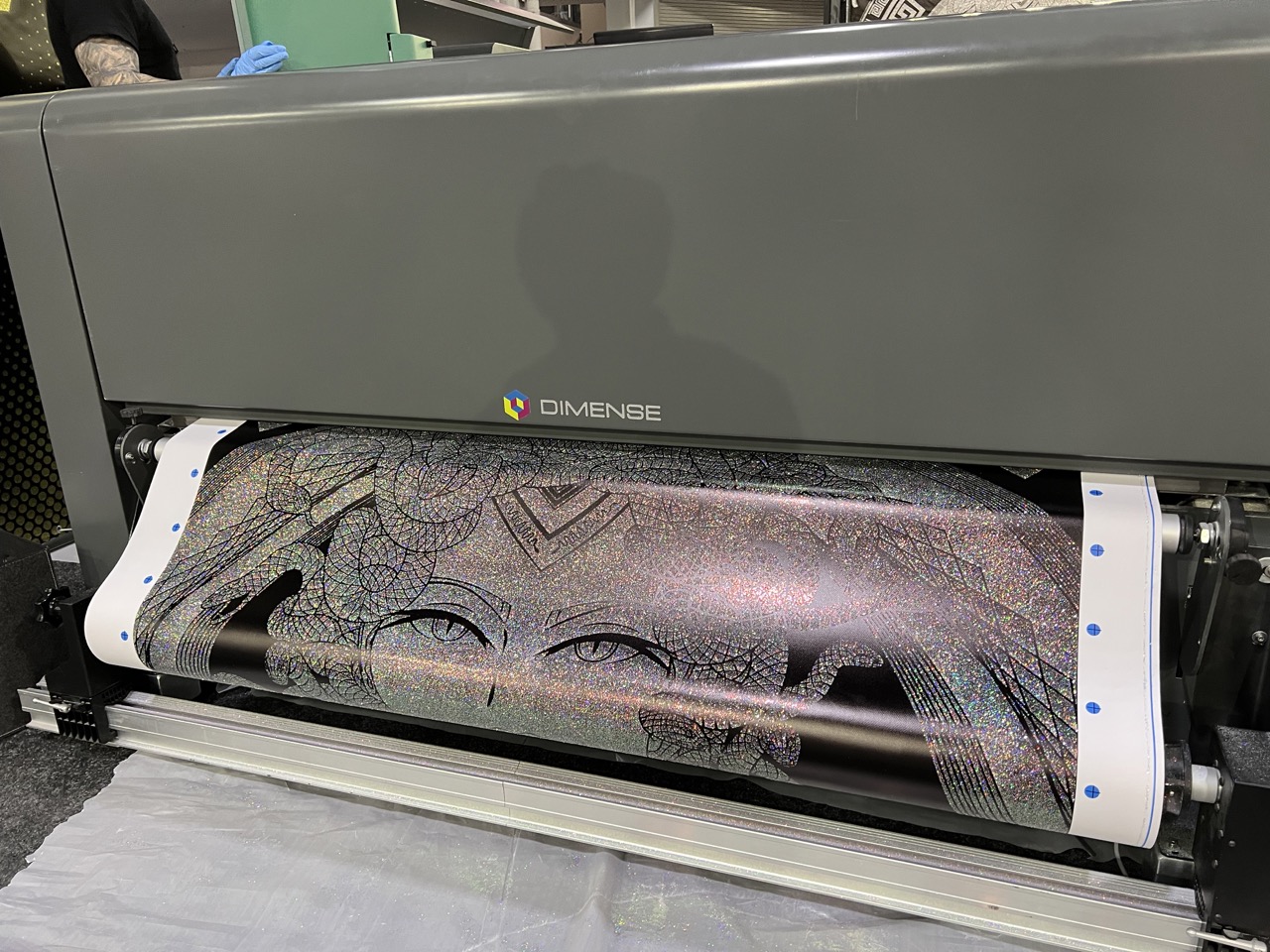

Embossed Looks and Glittery Finishes

One of the big stories on the print side at the show this year was the new partnership between Roland DG and the company formerly known as VEIKA, which invented the Ecodeco and DIMENSE printing technologies.

Now the partnership is showcasing a wide format product that you need to see, touch, and feel to believe. Using a special ink technology that creates an embossed look, signage and other products can have a 3-D and textured look to it without repeating the embossed pattern.

“So structure and motif can be perfectly matched to each other, or the structure may be completely different than the picture itself,” the company said on its site. “It all depends on the designer’s creativity.”

On the floor, they used signage from tactile-focused brands like Lego to draw viewers in to see how the Dimensor S printer can enhance a display using this 3-D look. The tech also works on products like calendars, boxes and packaging, and more.

It wasn’t just the embossed look that DG Dimense introduced this year, though. Things around the booth were noticeably sparkly.

The Dimensor SG printer the company had on site used particles like glitter, mica, gold, and silver through a water-based wide format enhancement system for digital prints that worked on any substrate to modify color and enhance a design.

Peak personalization

Everyone wants a product that feels like it was made just for them. If you can go beyond just a company logo and really hone in on the end-user, they’re much more likely to keep it. This can apply to kits where the box not only features the client logo, but also the recipient’s name printed on it. If you can incorporate it into the design of the box, rather than just slapping a sticker on it, that’s even better because it shows that it was intentional.

Not every product can perfectly personify the end-user, but some really can.