For as much progress as there has been in the print industry, it’s still common to see fulfillment and distributor locations use pick or pack lists to pull items and separately print a shipping label after the product has been pulled and packed. But there’s a bigger picture at play here.

Let’s say a warehouse center runs multiple laser printers that generate roughly 75,000 documents per day. Thanks to pandemic fallout, gone are the days when on-demand ordering and quick turnarounds are a given. With not a minute to spare, think about how many hours are spent following a two-step process to generate a form and label.

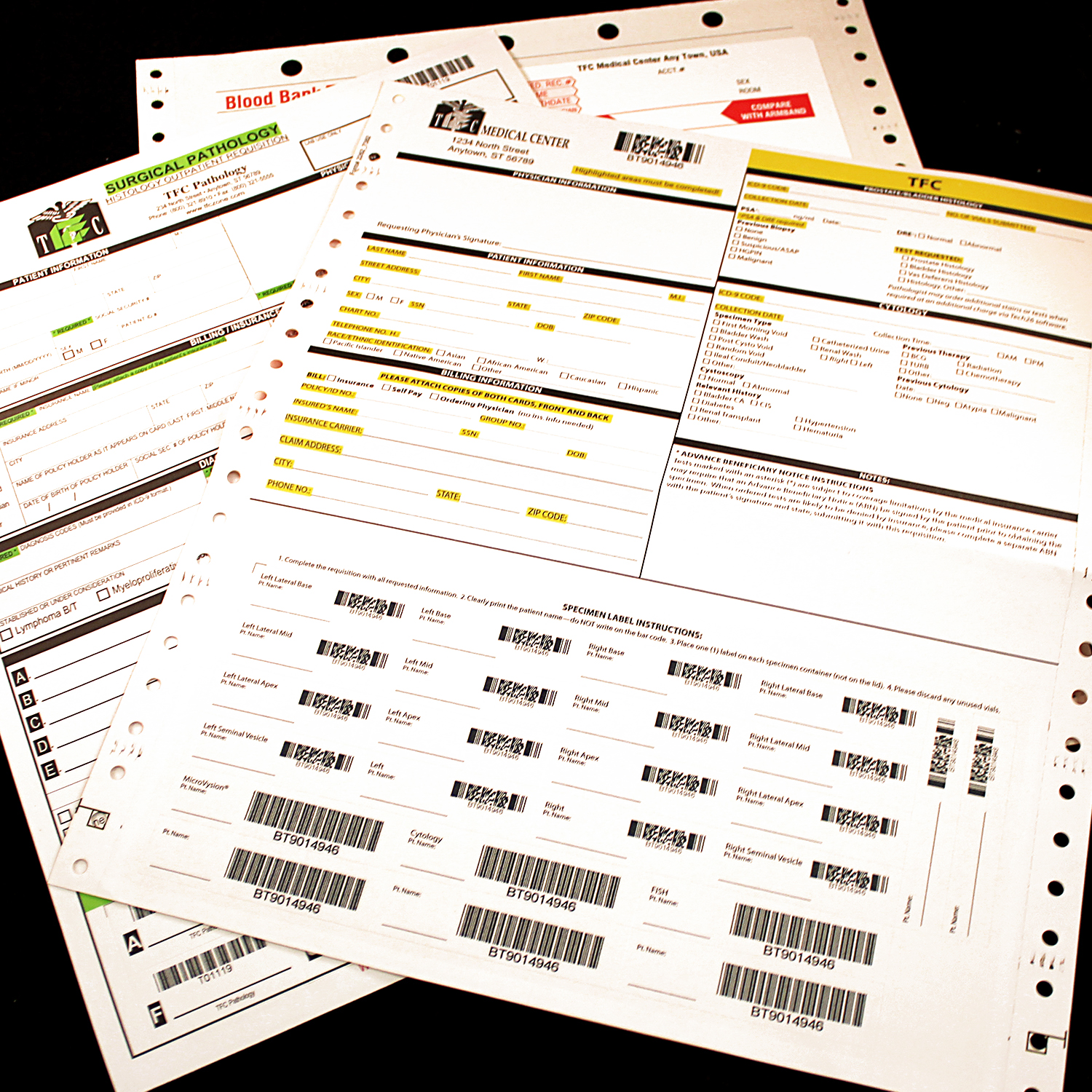

When too many parties are involved, how many packages might be mislabeled? This could result in returns, restocking costs, product damage and, most importantly, unhappy customers. A recent white paper titled “Thermal Integrated Labels: A new solution for high-volume distributor centers,” produced by Flesh Co, a Div. of Ennis Inc., Parsons, Kansas, notes that even a 0.5% error rate could lead to extra costs and lost revenue.

If there was a way to get around this, wouldn’t you take it? We’ve got good news. Integrated products allow for a card or label to be imaged at the same time as the carrier document, versus being printed at separate plant locations, thereby reducing the chance for error.

To learn more about where integrated products are excelling and how to balance their pros and cons, we spoke to Dee Brown, CDC, director of sales for Flesh Co, and John Short, marketing director for NAStar Inc., Middleton, Wisconsin.

What’s in a Name?

The combination of forms and labels is nothing new to the print industry, though the retail sector has truly embraced this format. For NAStar, a company whose primary customer base consists of flexo printers and suppliers, most of what it has seen is at the retail level, with shelf edge strips being a top category. Traditionally, integrated labels rely on a unique adhesive construction that allows liner material to transfer the adhesive to the back of the printed document. A die is then used to cut through the facestock, and positioning of the die cut is one area that must be considered. Without care and precision, a cut through the transfer line may occur.

According to Short, customers are looking for eco-friendly options. In response, NAStar developed TwoFer linerless label solutions.

“You’re basically taking a linerless pressure-sensitive construction, laminating it to a form, and then you have a label without any clear film, without any liner, without any waste,” Short says.

In a recent sitdown with Short at PRINTING United Expo, he shows me how it works. From his bag, he pulls out what appears to be a sheet of yellow pressure-sensitive material. He explains that a converter laminates the cardstock and then die cuts.

Short peels a part off, exposing adhesive that functions as a liner. The tag, he explains, goes over shelving with no adhesive on it — that’s the part that can be recycled. Half the material equates to roughly half the cost and material to ship with zero waste and half the environmental footprint.

“Why would you use this linerless pressure-sensitive liner?” Short poses. “Just take tag stock and perforate it. And I’ve wondered that too, but the reason is it’s obviously considerably more expensive. It’s a label thing basically, so rather than taking the time to bend, fold, tear, add all those perfs, you just take them off one at a time. They use yellow because they can see where, from a labor perspective, what tags have been used.”

Other verticals also can benefit from the convergence of print products, including education, transportation, hospitality, manufacturing, insurance or healthcare, the latter of which happens to be where Flesh Co sees the most activity. “The key is finding out what products they use and see how you can streamline workflow by using integrated products,” Brown says. “The name really says it all.”

Chain of custody forms for labs and medical facilities are a core product for Flesh Co. To nobody’s surprise, during the height of COVID, requests for these forms increased dramatically to meet the demand for testing. But as Brown points out, chain of custody forms have staying power.

“Chain of custody forms — whether it is for routine lab work, health screenings, drug testing or COVID testing — are an integral part of our healthcare system,” she says, adding that while lab form orders are steady year-round, surges in demand coincide with insurance open enrollment periods. “It is essential that the product works as intended and the numbering is accurate.”

Taking Care

Brown reminds distributors that since integrated products allow for everything to be printed at once, there are fewer worries about mismatched colors, numbering or other important information. Ideally, that leaves customers with a highly efficient document that boasts a cohesive look. But that doesn’t mean distributors and suppliers can coast through production. For example, cut sheet paper is susceptible to moisture from dampness or humidity, so if the laser printer lives in a hot, dusty warehouse, curling can be a problem.

“Integrated products should be stored as any other form, in a cool, dry, climate-controlled area,” Brown instructs. “As with any laser sheet, they should be taken to the area they are going to be printed. Packaging should be opened, and they should be acclimated to that area before loading into the machine. Laminates are available for all types of printers. It’s very important to know what the forms will be printed on so the correct laminate can be chosen.”

If the product is a label, distributors should know what the label is going to be adhered to and if there are any special properties surrounding its end-use. “Does it need to go outside?” Short asks. “Is it high humidity? Is it refrigerated? Is it in the freezer? There are a lot of different variables. We’ve gotten down the road in projects where they’re doing thermal transfer and they go, ‘Oh, we just found out it’s the same material, but it’s actually direct thermal.”

A Little Patience

Supply chain tension has been well-documented across the board, but Brown admits no one expected it to carry on this long. Historical two-week lead times are now in the four- to six-week range. Brown is direct in her advice.

“Both manufacturers and our distributor partners must continue to be upfront with the end-users so there are no surprises,” she says. “It is still important that orders be placed early enough to allow for the acquisition of materials.”

For Short, who says NAStar is still feeling the effects of the UPM strike that ended in April, obtaining liner is challenging for everyone, so the TwoFer linerless solutions have eased some of that burden. In addition to sheetable liner for lay-flat applications, allocations and rising paper costs have been tough. For the most part, he says, customers have been patient.

“I mean, they get it,” Short says. “They’re open to different things and we’ve been somewhat fortunate in this climate in particular for the last year in that we’ve been able to fulfill customer needs when other suppliers couldn’t.”