If you had asked Chris Wells eight years ago if he thought adding embellishments with digital printing was beneficial, he would have told you it was a waste of money. “That was when digital was used to get people out of jams,” he says. Now, he considers himself a convert.

Wells, who is the executive vice president of Lowell, Massachusetts-based DS Graphics | Universal Wilde, specifically notes a shift toward more direct mail incorporating tactile elements because of the positive response it seems to elicit.

“Digital is not [for runs of] 500 anymore; you can go up to 5 million,” he says. “With that, and how inkjet technology has expanded the digital marketplace, I’m a converted fan. It’s become a primary marketing channel for a lot of our customers that used to be just offset, and digital only for things they really cared about.”

Wells has come a long way from thinking adding value with digital technology was a “waste of money,” but that’s not the case with all print services providers (PSPs) and print buyers. While there are many commercial printers that have embraced enhancement opportunities in digital printing, there is still room for expansion in the market.

Lisa Cross, a principal analyst at NAPCO Research, explains that in a survey completed by her team, 202 PSPs that offer digital printing were asked why they don’t offer print enhancements. Of the respondents, 63% said there is a lack of customer demand. When asked what challenges those companies face in growing the adoption and utilization of enhanced printing capabilities, respondents’ top three answers were lack of customer demand, cost, and lack of value.

Somewhere between Wells’ perception and the perception of the respondents to the survey, there is an opportunity in the market. It’s a matter of figuring out where to find the opportunity and how to take hold of it, along with understanding the challenges.

Develop a Plan of Use

According to Kevin Abergel, president and founder of Taktiful, there is a “clear delineation between the businesses who are successful with this technology, and those who aren’t.”

Those who aren’t, he says, are the companies that subscribe to the “build it and they will come” attitude. In fact, Abergel recently started looking into the utilization rate of digital embellishments.

“For people who have fifth and sixth color options on their digital presses, we’re finding that [there is a] 5% or less utilization rate of those specialty colors in overall production,” he says. “They’re buying a Ferrari, and they’re driving it to go grocery shopping on Sunday afternoons, but they’re never taking it to

the track.”

What’s happening, he explains, is that some companies are investing in equipment because they think their clients will like it, but they’re not “doing the work to get their customers to like it.” That means companies need to be prepared with applications that can be embellished and market those capabilities, but first, PSPs should test the waters.

David Baird, president and CRO of Arden Hills, Minnesota-based Truly Engaging, tested the waters with a process he calls “faking foil.”

The company — which started out as Magnet Street before expanding into a resource for wedding invitations, save-the-date cards, baby announcements and, of course, magnets — wanted to test customer demand for foil on magnets. Rather than jumping in headfirst, the team started by using a sleeking process.

“It was good enough to prove that there was an appetite for it,” Baird says. “But, it made us think, ‘We need to find a good solution.’ To be honest with you, we weren’t sure we were Scodix material. … Are we big enough? Can we really warrant that?”

It turns out, they were. After Truly Engaging installed its first Scodix device — a Scodix Ultra 1000 — Baird says they “couldn’t put foil on enough things fast enough.” It has since installed a second Scodix device, a Scodix Ultra 2000.

Understand the Process, Market Opportunities

Once it’s determined that there is a need for digital enhancement equipment, it’s crucial to “be prepared,” Jon Otto says. Otto, who is the CEO of Visions Inc., a Brooklyn Park, Minnesota-based commercial printer that operates a Scodix Ultra Pro, says that’s the one piece of advice he has for a PSP interested in entering the digital embellishing market. For example, substrates will no longer lay flat after being embellished.

“When you embellish something, you’re putting a textured layer on it,” he says. “When it starts stacking up, it does not lay flat like ink on paper. Depending on where you place your enhancement, you can have a very bumpy, wavy stack of paper. … Be prepared to adjust your current finishing methods.”

The big advantage, Otto notes, is that “it brings creativity back to printing.”

Otto also points to versioning and variable data printing capabilities, which can make a big impact on customers. Not only does Visions do personalization on its HP Indigo 12000, it uses its Scodix device to apply variable polymers and digital variable foils.

Having a firm grasp on what the technology can do is crucial. Summer Gould, account executive at Neyenesch Printers, a commercial printer based in San Diego, California, explains that different enhancements can achieve different goals.

“Different embellishments are going to help you do different things,” she says. “It’s not like we say everybody should use soft touch no matter what they’re doing, or everybody should use foil because it’s sparkly. That’s not going to fit with every campaign … It really becomes a 1:1 relationship. What are we trying to do? Who are you? And how do we mash those things together to get you the most bang for your buck?”

Since sustainability is increasingly becoming a concern for many print customers, it’s a consideration PSPs need to make. Malcolm Glynn, graphic communications business manager at Xerox, explains that there is an environmentally conscious element to investing in a device that includes additional colors in-line for applying embellishments.

“There are no special chemicals, no toxic solvents, or anything,” he says. “There’s no additional energy required and no emissions. It’s just like printing on a standard four-color digital press, but on the press in-line with additional colors added. There’s definitely an environmental benefit.”

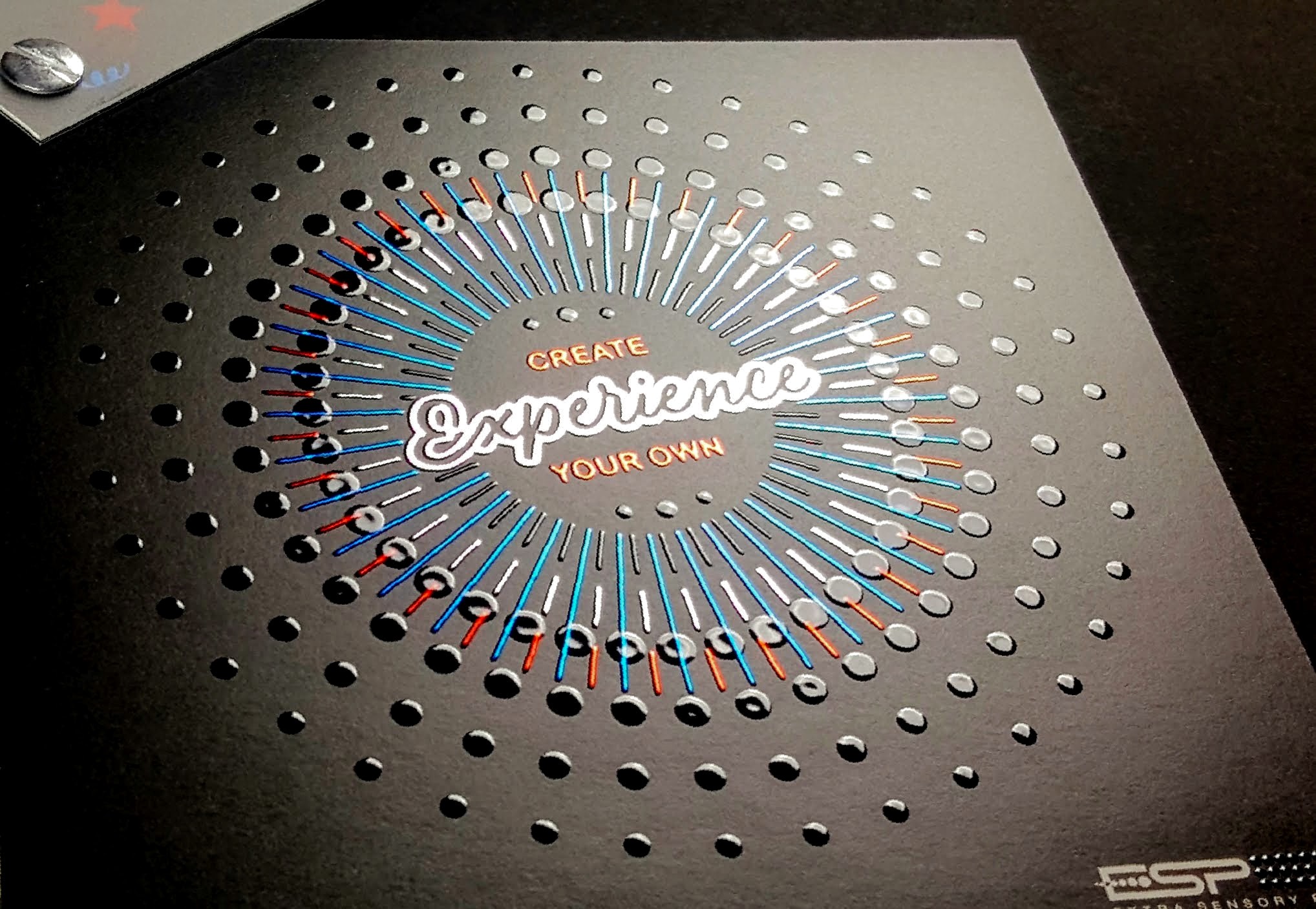

Once it’s determined if there is a demand for digital embellishments in-house and the PSP has a firm grasp on the process and the customer’s goals, it’s helpful to dive into the trends. Adding a tactile element to a printed piece can influence the recipient to spend a few more seconds with the piece, Anthony Gandara, partner alliance manager for Duplo USA, notes. This is something Gould echoes.

“I’m all about the tactile stuff,” she says.

There are ways to incorporate tactile embellishments into a design seamlessly, such as a rubbery touch on an image of a basketball or football, or the feeling of sandpaper, depending on what the goal of the piece is, Gould explains.

“Soft touch feels like you’re petting velvet,” she says. “All those kinds of things are really fun for recipients, and they have a tendency to continue to [touch] them.”

One tip Abergel offers is to pay attention to macroeconomic trends. “You kind of see what’s going on,” he says. “It’s very easy to put your printer lens on. … In many cases it’s common sense. You take a 50,000-ft.-view and suddenly all that makes sense because macroeconomic trends equal what’s really going to happen in the field.”

PSPs that are interested in the use of metallic colors could look to the lottery for inspiration. Glynn explains that one of his company’s customers is using embellishing technology to print tickets for the national lottery, and digital technology enables PSPs to quickly and easily produce different versions, depending on the needs.

“You want these to look nice,” he says. “You’ve won a prize, so they print it in gold. The next month, they’ll print everything in silver to make it look and feel different.”

To create a foil effect, metallics can be used on invitations, stationery, and greeting cards, Glynn says. While metallics alone can be quite eye-catching, mixing these colors with other vibrant colors, such as fluorescent pink or CMYK, can create an iridescent look.

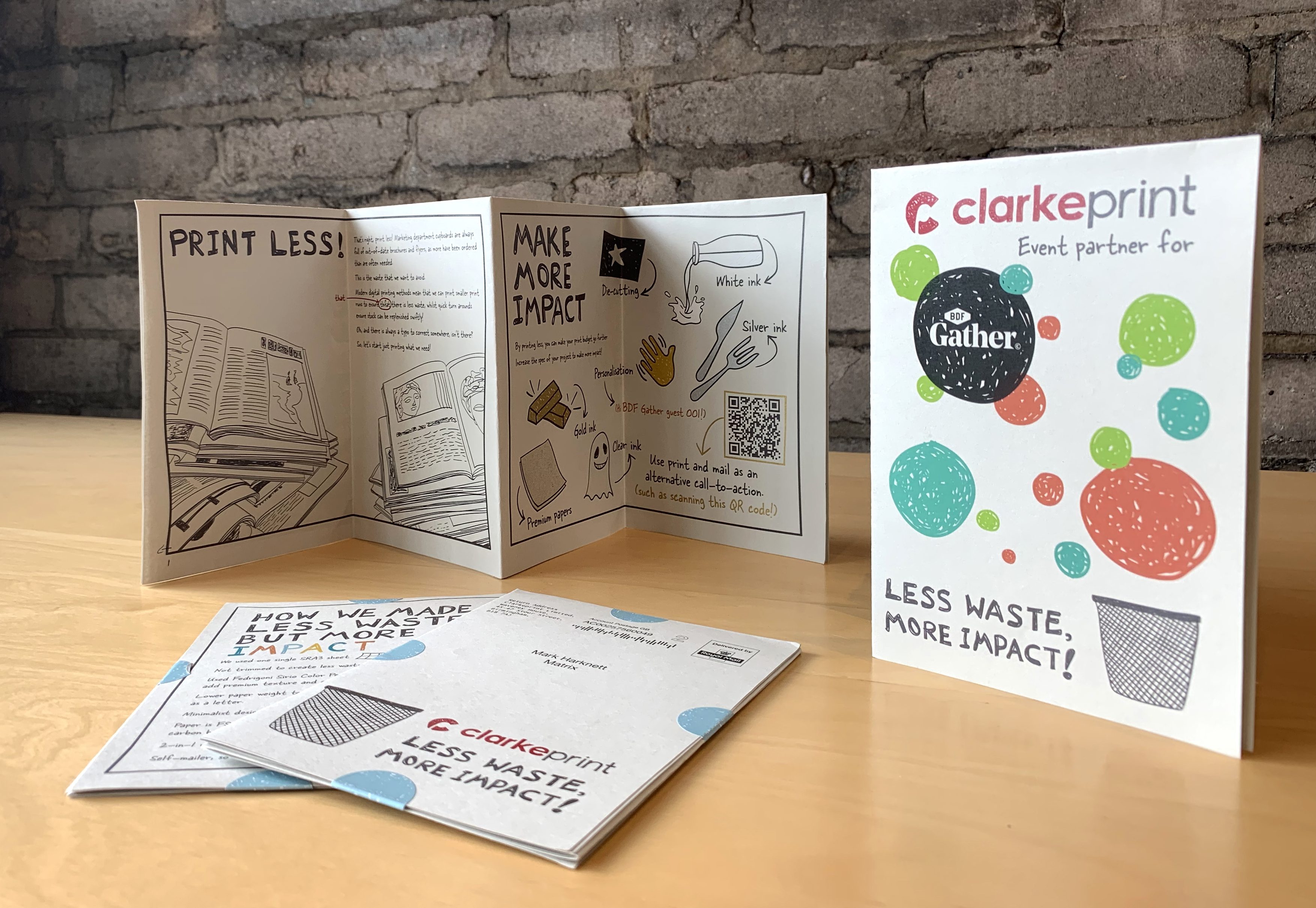

For PSPs working with colleges and universities to produce direct mail, embellishments are a great avenue to add an element of differentiation. Many times, the team at Truly Engaging adds a magnet tipped onto a postcard, to which it will then add foil and

varnish.

“A 17-year-old is about to get 100 pieces of mail in the next 45 days,” Baird says. “How are we going to be different? We’re even embellishing our stickers. Not only do we attach magnets to the postcards, we’re doing stickers, which have gotten wildly popular. Magnets are a little more old school.”

He explains that colleges love “highlighting that extra piece of their logo with a little bit of raised varnish.”

If direct mail for colleges and universities isn’t of interest, some vertical market segments that saw a dip during the COVID-19 pandemic have come back full force. Abergel points to the use of spot UV and raised foil in different segments, such as cannabis and book covers.

“Book covers are coming back in a big way,” he says. “You’ll see a matte lamination and some kind of foil, raised element, and varnish to create a really highly embellished product.”

He also points to an opportunity in the gaming and entertainment vertical, which is something Otto is familiar with. Visions uses a cast and cure technique to apply holographic embellishments to playing cards and trading card games (TCG). The company responds rapidly to orders for new trading cards with added foils and raised textured enhancements. In the TCG space, some brands are releasing new versions every few months, which creates a large opportunity for a PSP.

“There’s churn with TCG,” he says. “And when you’re talking about churn, you’re talking about introducing new cards into the market on a more frequent basis. It allows the games to stay fresh and to have a life of their own.”

However, with both tight and critical deadlines, digital technology is necessary. “You don’t have the limitations of traditional means,” he says. “With these cards, it’s basically every three months that a new set is implemented, and we can respond rapidly with the volumes required.”

Since Visions also caters to the casino segment, Otto says that using foils and soft-touch laminates are popular. Combining these effects, along with unique shapes, creates a “rich, elevated sense of touch that’s perfect for the high valued customer,” he says.

For PSPs working primarily in the commercial space, digital embellishing equipment can be a workhorse option. DS Graphics | Universal Wilde runs an MBO FC 23 in-line web coater with its Canon ProStream 1800 inkjet web press, something that Wells says it runs daily. “It gets used all day, every day,” he says. “We do a ton of direct mail, postcards, and self-mailers.”

Although the company initially encouraged its customers to use the coating technology for protection through the mail stream, that has changed. “A lot of our direct mail clients, particularly B2C, are getting much better response [rates] because the UV coating just stands out a little bit more,” he shares.

Differentiation is really the shining star of adding enhancements to digital pieces. Gandara explains that printing alone is no longer “enough.” While there is still a demand for printing, printers can’t survive by only printing a product. They must find a way to make it stand out. “We have to make it more interesting,” he says. “And that’s where embellishment comes in.”

Gandara points out that Duplo first introduced its spot UV coating technology to help PSPs get their “foot in the door for embellishments.” He says it’s a simple technology that brings value to a product. With equipment like Duplo’s DuSense DDC-8000, PSPs can offer spot UV and foil enhancements to impress customers.

“Foil is really powerful. Even just the foil by itself, but the spot UV adds a sensory aspect to it.”

—Anthony Gandara

Market Your New Capabilities

Marketing capabilities and the power of embellishments are made easier when the brands are on the same page as the PSPs. Glynn explains, “three-quarters of marketing people really believe that print enhancements give their brand a premium look, and make it look and feel better.”

One of the best ways to bring about awareness to the remaining customers who don’t understand its value is to provide samples of enhancements. Based on her research, Cross says samples can be highly influential.

“When we survey print buyers and influencers, print samples are very influential in getting a sales call,” she reveals. “I did a survey last year and 67% said a print sample demonstrating a provider’s capabilities was very influential. That was the No. 1 response.”

Although Cross admits that people are probably tired of hearing the samples suggestion, she questions how many PSPs do provide samples of embellished work. When print providers were asked in a survey how they educate their customers on enhancements, 60% said “samples,” and 42% answered “direct mail pieces that showcase the special effect.” Additional responses included exhibiting at events and open houses. Surprisingly, 16% of respondents answered that they do not educate their customers.

DS Graphics | Universal Wilde is not part of that 16%. “Tours are by far the most effective way to show people what we do,” Wells explains. “We also do a lot of webinars, videos of the device running, and samples.”

Giving clients samples of what their job would look like with embellishments is another strategy, one that Truly Engaging takes advantage of. “When we’re making samples for our large clients, we show it to them with the embellishment and without,” Baird explains. “Nine times out of 10, they say, ‘Now that you’ve showed me, I can’t look away.’”

Abergel acknowledges that the printing industry hasn’t necessarily been the best at marketing its capabilities in the past. “Those who are successful with this, as with any technologies, are putting the marketing and the salespeople behind it,” he says. “Organizational alignment is important for this.”