This article originally appeared in Apparelist. To read more, click here

If you’re new to the wide world of apparel decoration, and you’re looking into investing in some new equipment, this article is for you. And if you’ve been in the biz for a while, and you’re looking at expanding your horizons and bringing a new print process in-house, this article is also for you.

Sit down, grab your coffee, and get comfortable as experts in screen printing, embroidery, heat printing, and digital printing (direct-to-garment and direct-to-film), share their expertise.

Is Now the Right Time?

You want to invest, grow your capabilities, or expand a current setup, but you’re wondering if it’s the right time. Sources weigh in on when to buy.

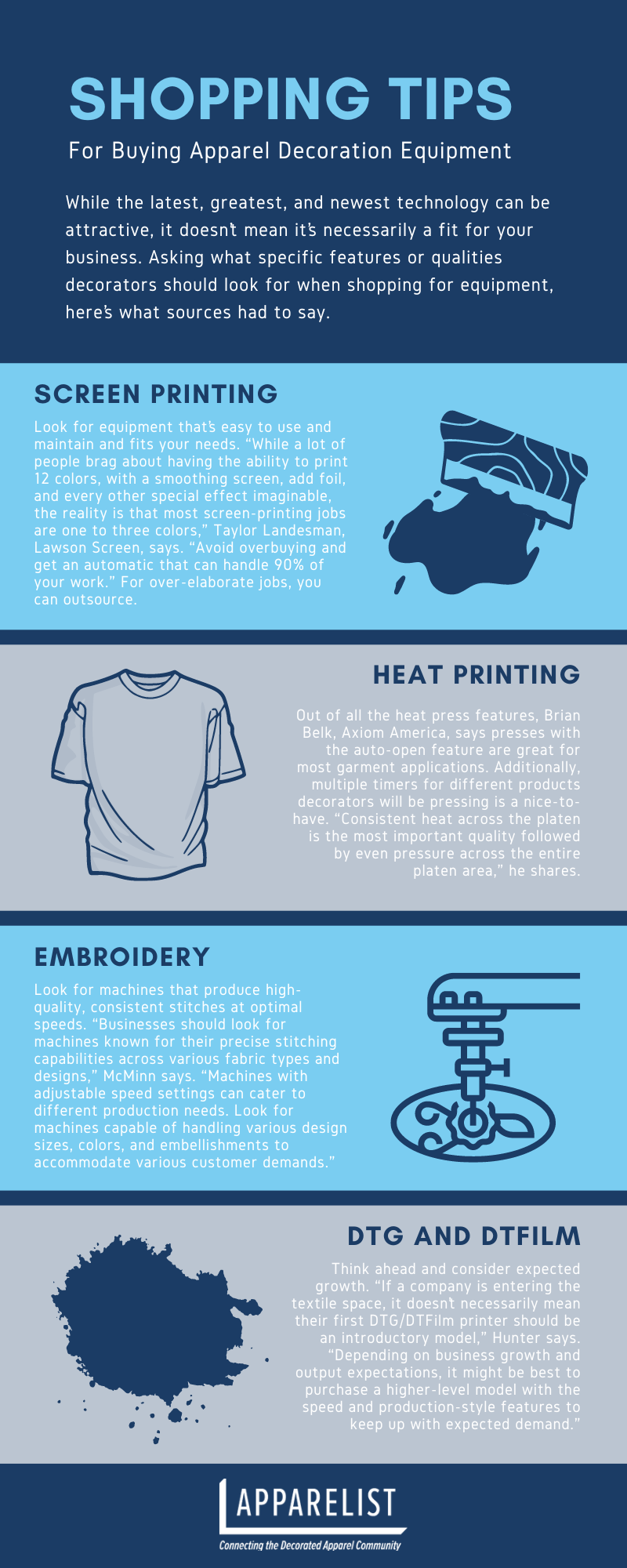

“There are a few times when an equipment investment simply makes sense,” Taylor Landesman, vice president at Lawson Screen & Digital Products, says of screen-printing equipment. “Being able to anticipate growth of a particular market is a great opportunity to get equipment, as it lets you get in early and establish yourself as a dependable decorator.”

Another time to consider investing in equipment is when your current technology isn’t reliable. “If you are having inconsistencies with your existing product and it’s over 10 years old, it could be a good time to consider,” shares Brian Belk, managing director at Axiom America LLC. “If your production is bottlenecking at the [heat] press or if you have clients that are so time critical you are going to lose business if you aren’t able to supply in a timely fashion, it’s a good time to add an additional press. Often an operator can handle both presses and speed up the process.”

Travis McMinn, part owner of Stitch It International and owner of BYLD Marketing, says one of the key signs is when production demands start to outpace equipment capacity. “It’s like, we’re pushing the limits, experiencing more breakdowns, and struggling to keep up with orders — that’s when I start thinking it might be time for an upgrade,” he says. Agreeing with Belk, he says keeping up with technology is important, especially when your current setup isn’t performing at its best or isn’t compatible with newer software. He says staying competitive means staying ahead of the curve.

Beyond these tell-tale signs that it might be time for new equipment, it’s also key for decorators to consider their financials. Business owners want to dive into the numbers before getting into a payment on new equipment, asking themselves: Will it make sense for my ROI?

“I’m always crunching the numbers, weighing the costs of maintenance and repairs against the benefits of investing in new equipment,” McMinn adds. “It’s all about finding that balance between affordability and long-term value.”

Ultimately, he says, it’s a gut feeling combined with some careful analysis of your business. When there’s strain on demand, you’re behind in the technology on the market, output quality isn’t at its best, and the numbers make sense, it’s the right time to invest.

New vs. Used

So, you’ve crunched the numbers and can see a clear path forward for purchasing equipment. Your next question might be whether buying new or used is a good idea. While there is one big draw to buying used equipment — lower initial cost — the scale tips in favor of new equipment for obvious reasons. New equipment often comes with technical support, training, warranties, reliability, and customization possibilities, plus the advantage of being up on the latest technology, which comes with greater efficiency and improved productivity.

“Purchasing new is always better than used,” Landesman says of screen-printing equipment. He argues that purchasing used leaves a business vulnerable and reliant on a stranger’s word about its reliability. In the long run, the larger upfront investment in new screen-printing equipment “amounts to very little” when you consider the 10-plus year life of the press, he notes. “Typically, a used machine is a combination of worn out and poorly maintained. There is little, if any, training, and you are left to struggle through figuring out how to get the best out of a machine that someone else couldn’t.”

For those buying a heat press, whether to expand into heat transfer printing or for curing direct-to-garment (DTG) prints, Belk says it’s difficult to make an argument for used equipment when small-format heat presses are relatively inexpensive. However, buying a used heat press might make sense when looking for a backup piece of equipment, he adds, especially if it’s lightly used and less than 50% off the retail price.

“If you are able to pick up a used press for pennies on the dollar, that is an obvious reason to consider used but otherwise, a new press is often a better decision,” Belk adds. “Considering the cost of time and cost of damaged goods, saving money on something that might not be accurate or consistent could make you lose more money than you save.”

In addition to the “allure of a lower initial cost” that comes with used equipment, McMinn says the lack of lead time on used equipment can be enticing, especially for those on tight budgets itching to get started.

“If you’re lucky enough to stumble upon a well-maintained piece of equipment, you might just find yourself scoring a great deal complete with extra accessories or software,” he adds. “However, it’s not all sunshine and rainbows when it comes to buying used equipment. The biggest concern? The potential for mechanical issues.”

Key Questions to Ask Suppliers

Taking the new route, decorators need to ensure they’re getting the equipment that’s best suited for their needs and customer demands. When evaluating potential equipment, decorators can ask some key questions of suppliers and manufacturers to identify if their company and equipment is the right fit.

Taking the new route, decorators need to ensure they’re getting the equipment that’s best suited for their needs and customer demands. When evaluating potential equipment, decorators can ask some key questions of suppliers and manufacturers to identify if their company and equipment is the right fit.

Outside of understanding the machine’s specifications, software requirements, and cost, examples of these questions include:

- What warranty coverage do you offer on the equipment?

- How often do customers use the warranty?

- How often does the equipment require maintenance?

- Who performs maintenance/fixes?

- Where can I purchase spare parts?

- What ancillary accessories are available or needed?

- What training and technical support is available to customers?

- Does this machine allow for future upgrades and scalability?

- Do you have customer references or case studies?

When it comes to warranty, buyers need to know what it includes and how long it lasts, McMinn stresses, in addition to any special terms, conditions, or limitations. In the event a machine goes out, decorators need to know how it will be handled.

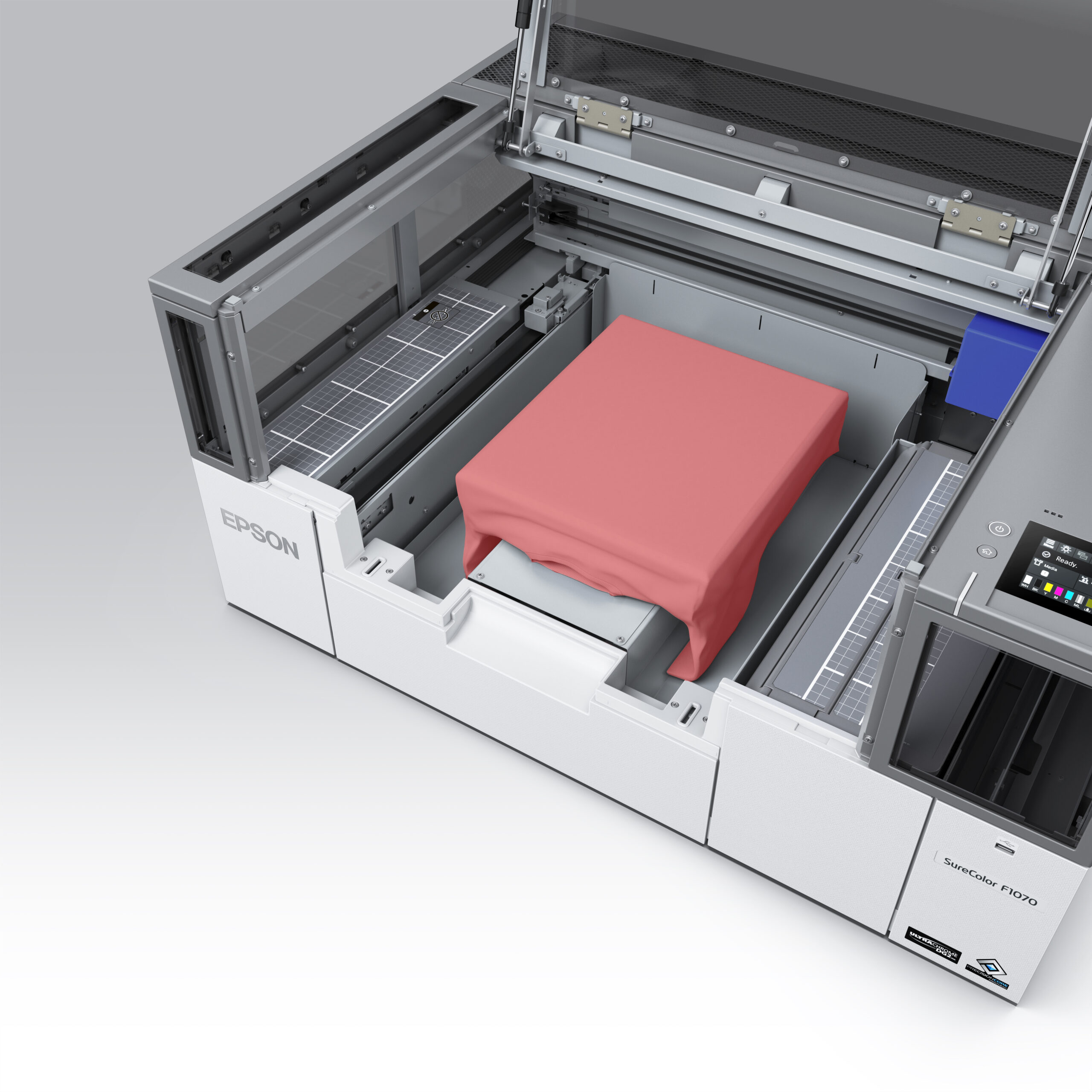

“Ask a manufacturer how long it takes to get on-site support if needed,” Lily Hunter, product manager, Epson Professional Imaging, Epson America, says. “For those manufacturers who are based overseas, ask about local support and inventory. Regardless of original price, if a printer is not operating and parts cannot be sourced or it cannot be fixed with on-site support quickly, it has the potential to derail deadlines and impact customer satisfaction.”

In that same vein, Landesman says it’s not only important to have equipment support but also a manufacturer who understands printing. “For support, a lot of times manufacturers are limited in their abilities to troubleshoot problems if the service issue is really a print issue,” he explains. “For example, if you are having a curing problem, the manufacturer might tell you the dryer is working fine, and your issue is with your ink or process. This forces you to go back to your supplier for help, who might blame the equipment. The lesson in this is to find a manufacturer who can provide both technical and print support.”

For embroidery machines specifically, McMinn stresses the importance of understanding stitching speeds, the size of the embroidery area, and the machine’s features, including if the machine will work with existing systems a decorator has in place or if an upgrade will be necessary for seamless integration.

And no matter the print process or equipment you’re eyeing, it’s a no-brainer that decorators need to understand the entirety of that process and all the ancillary equipment and accessories it requires, in addition to the total footprint.

“For DTG and DTFilm printing, a printer is just the start; decorators will also need a heat press and/or power applicator — depending on print type,” Hunter says. “It’s important to factor in the total cost of ownership of a purchase, as well as the amount of space needed, and the cost and labor required to house and maintain all of the different components.”

Businesses should also consider growth and ask suppliers how a specific piece of equipment accommodates that growth. Because buying new equipment can come with a large investment in money and training, looking a few years ahead can help businesses make the right decision and save money in the long run.

“When it comes to investing in equipment and thinking about scalability, businesses need to strike a balance between immediate needs and future growth,” McMinn adds. “We’re crunching the numbers, forecasting our growth trajectory, and evaluating whether the equipment can scale up with us. It’s about future-proofing our investment and making sure we’re not left behind as technology advances and market trends evolve.”

Because scalability can be tricky with equipment, Landesman advises owners to look at modular equipment and find out if there is a trade-in or -up program for when a shop outgrows its equipment.

Equipment Financing Breakdown

Shopping for new equipment can be exciting until you get to the purchasing and paperwork. This stage of the buying cycle can be overwhelming because it comes down to cash or credit — aka, leasing, loans, and equipment financing.

Smaller equipment like heat presses don’t necessarily require or qualify for financing because of the “small dollar volume,” Belk explains. “If cash flow is tight and a new press is needed, a credit card with 0% over a few months is probably your best bet. Otherwise, cash is king.”

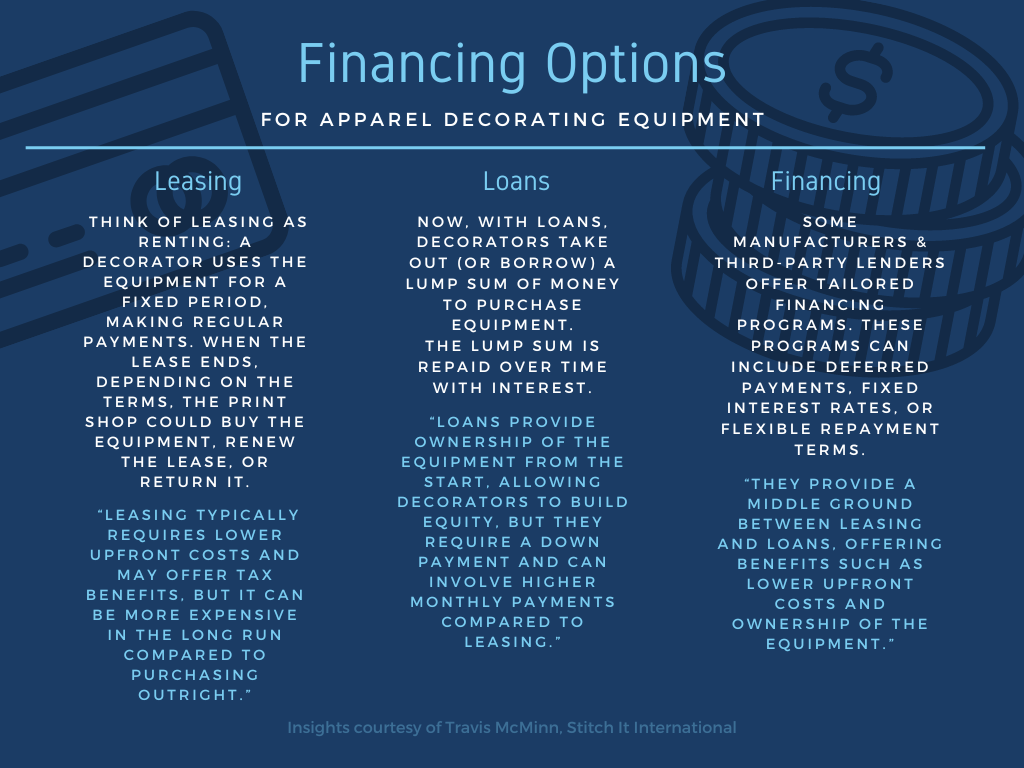

For those purchases that do require financing, McMinn breaks down leasing, loans, and financing programs in simple terms:

Now that you understand the basics, how do you know which option to choose? It all depends on your business’s budget, cash flow, and if you want to own the equipment. Tax implications can also play a role in deciding the best financing option.

“Leasing may be more suitable for decorators with limited upfront capital or uncertain cash flow, as it requires lower initial costs and predictable monthly payments,” McMinn explains. “If decorators prioritize ownership and equity, loans may be the preferred option, allowing them to build assets over time.” However, he says, leasing gives print shops flexibility to adapt and upgrade down the road without jumping into a large ownership investment.

The last thing to consider, McMinn says, is tax implications. “It’s essential to consult with a financial advisor or tax professional to understand the tax implications of each financing option, as they can vary depending on factors such as depreciation, interest deductions, and lease terms.”

Whether you’re looking to add new print services to your arsenal, you need to double-down on what you already having running, or you simply need an upgrade, investing in your business can support growth and longevity if approached right. If you “find yourself turning away orders or falling behind on deadlines,” Hunter says it might be time to say yes to the press.

“As new equipment comes out, there are refreshed features and benefits designed to better support print shops,” she notes. Investing in that new technology may just be the key to keeping up with orders and offering customers better products.