Key article takeaways:

• Pretreating is a vital step in DTG printing because it creates the necessary surface for white ink to bond and produce vibrant, accurate colors.

• Visible “boxing” or staining after pretreatment is often caused more by the shirt’s fabric and manufacturing variables than by the pretreatment itself.

• Shirt quality and cost do not always correlate with better pretreating results, making it essential to test and choose garments that pair well with your specific DTG process.

If you own a direct-to-garment (DTG) printer, or are looking into purchasing one, it’s widely-known that the pretreating is one of the least favorite processes. It is, however, absolutely necessary in achieving a great-looking print on your garment. As a manufacturer of DTG pretreatments, we wanted to clarify what is going on when you pretreat, why you get the dreaded “box,” and why your “favorite” expensive shirt may not be the best for your DTG pretreating needs.

What is pretreating?

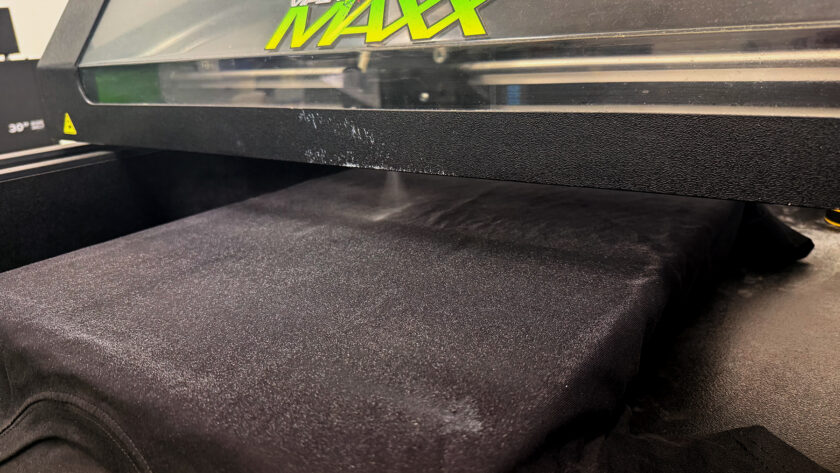

Pretreating is the process that allows for successful digital white ink printing on a garment. It is a necessary step before the shirt is printed where a liquid pretreatment is applied to a garment, typically via a spray application, and then heat set to create a “foundation” upon which the DTG printer (Brother, Epson, Aeoon, M&R) then prints the graphic to be applied to the shirt.

What Does Pretreating Accomplish?

Pretreating accomplishes two basic functions. You can think of it like primer for drywall. A painter would typically apply a coat of “primer” on the drywall to act as a barrier between the drywall and the final coat of paint. This is done so that the final coat of paint does not soak into the drywall, leaving your finished paint job looking rather spotty and uneven due to different absorption rates of the paint into the drywall.

Pretreatment acts just like that primer to create a barrier between the shirt and the white ink printed on the garment. It allows for a better bonding surface for the ink when printed on the shirt.

The pretreatment also reacts with the white ink, causing it to slightly firm up (not being completely wet or “kicked over”), allowing the CMYK ink being deposited onto the shirt not to mix and muddy on a wet white ink (like trying to paint one color over another when the paint is still wet and they mix together).

Read the rest of this article on Apparelist, a publication of PRINTING United Alliance, ASI’s strategic partner.