There are plenty of jokes about the merchandise that doesn’t end up on the field, ice, or locker room after a major championship – the kind of stuff made for the losing team that sadly ends up in landfills or gets shipped abroad through nonprofits. (Somewhere in the world, there are people who believe the early ‘90s Buffalo Bills were a dynasty with four straight Super Bowl wins.)

Printing and apparel decoration has changed, though, and now there’s less risk of creating obsolete merchandise for the losers, while also making capitalizing on huge demand for winner merch more effective.

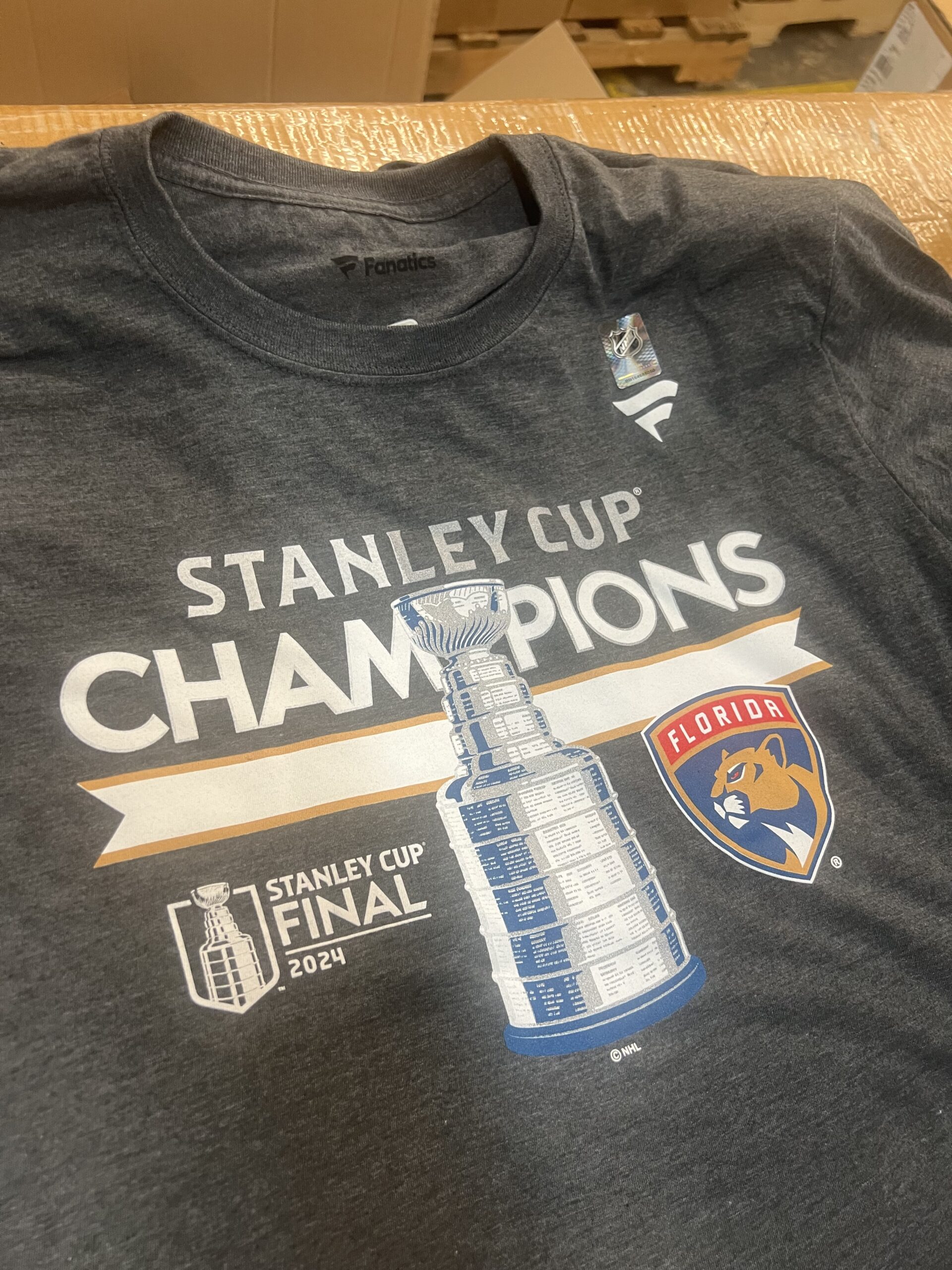

After the Edmonton Oilers rallied back to bring the National Hockey League’s Stanley Cup Finals to a 3-3 tied series and a thrilling Game 7, the championship was anyone’s to win. So, the folks in the merchandise printing house couldn’t get comfortable and start firing off Panthers’ gear just yet. But, when the final buzzer sounded Monday on Game 7 and the Panthers prevailed, Atlas Embroidery & Screen Printing (asi/126900) was ready to go.

Big Game Swag, Big Time Pressure

Atlas is a back-end decorator for Fanatics, meaning that it works throughout the year for the country’s major sports leagues, producing swag at a flash for major championships like the Super Bowl and Stanley Cup. Atlas President Adam Cohen, coming off of the rush of churning out Panthers’ merchandise, explains what goes into these sorts of jobs, and how decorators can bring “hot market” mindsets to all of their orders.

For starters, the company had two sets of approved graphics ready to drop the second the Stanley Cup concluded: One for Edmonton, one for Florida.

“We set up on either side to produce merchandise for whichever team wins,” Cohen tells ASI. “It’s called hot-market environment, hot-market scenarios. If the game ends at 11:30, we’re printing at 11:31. And then we’ll print all night long and have pickups from Walmart, Target and other stores all throughout the night. That’s how people get their merchandise first thing in the morning.”

Atlas prints off a limited pre-produced quantity of both teams’ gear just in case, since there are the theoretical locker room celebrations that can’t wait until the morning.

To get these high-volume and quick-turn jobs done, Atlas has 10 M&R automatic screen printing machines, 100 heads of embroidery, and other equipment to apply patches at their Florida headquarters. To supplement that, they have a secondary facility in Las Vegas, where they have three new Roq screen printing presses.

“We can print 34,000 shirts a day out of Florida,” Cohen says. “And we do another 10,000 or so out of Vegas.”

High Speed, High Stakes

When the product is this time-sensitive, every mistake is costly. Cohen has had to deal with some potentially devastating blows over the years.

“I’ve had a power outage in the middle of it,” he says. “That’s about as bad as it gets.”

After an impassioned plea to Florida Power & Light, things were back up and running, but not without some damage to the process.

“It cost us a couple hours of production, which is thousands of shirts and delays everything,” Cohen says. “We’ve ended up with art where we found misspellings after it’s been proofed four times – we’ve had that happen once and got it fixed. You have employees who don’t show up for their all-night shift.”

Everything went smoothly for the Stanley Cup job, though, and Cohen says the hometown pride might’ve injected some extra pep into the production floor.

Big League Lesson: Control As Much as You Can

Even for decorators that aren’t working with such big names as the Stanley Cup champions, Cohen says it’s good to bring that championship mentality to everything you do, and to maintain control over every variable possible. As a production partner for Fanatics, as well as Top 40 distributors like BDA (asi/137616) and PromoShop (asi/300446), Atlas decorates products for major consumer brands and Fortune 500 companies, all of whom desire quick turns on their orders, even if they don’t have to stock a locker room or get shirts in peoples’ hands by the time a parade starts.

“All day, every day, we’re making merchandise for Coke and Pepsi, Constellation, FedEx, UPS, Home Depot and Lowe’s, all the banks, all the car companies,” Cohen says. “The big dogs appreciate the quick turns and the attention to detail for the things we do. A lot of the clients we used to have before 2017 when we kind of exited the contract world, it was different. It was chewing on a whole lot for a lot less return. Now we chew on a lot, but we’re very incentivized to do it.”

To maintain this level of control over the production process, Atlas manages every step of the process that it can. It doesn’t manufacture the blanks, but just about everything on the decoration end is done in-house. This results in minimizing chances of things-outside-your-control going wrong and delivering on the schedule as promised.

“Everything we build is a full package with the blanks, the inks, the screens, the films, the creative development, so we have complete control over all the incoming goods, which actually allows us to do what we say we’re going to do,” Cohen says. “Without complete control, it’s really hard to turn things in a day or two days.”