You’ve likely seen on TV (or even in person, if you’re lucky) what an arena looks like before a playoff match. The chairs are all covered in T-shirts and/or rally towels. Once the seats fill up, those shirts become a sea of screaming fans all in one matching color. It’s an awesome spectacle that adds to the energetic scene of sports.

What you might not know is how much work goes into getting those promotional items into the arenas and onto the seats. Something Inked, a Nashville-based distributor, is responsible for those promo items for just about every team in the NBA or NHL, so they’re more than familiar with what it takes to make a promotional event like this happen.

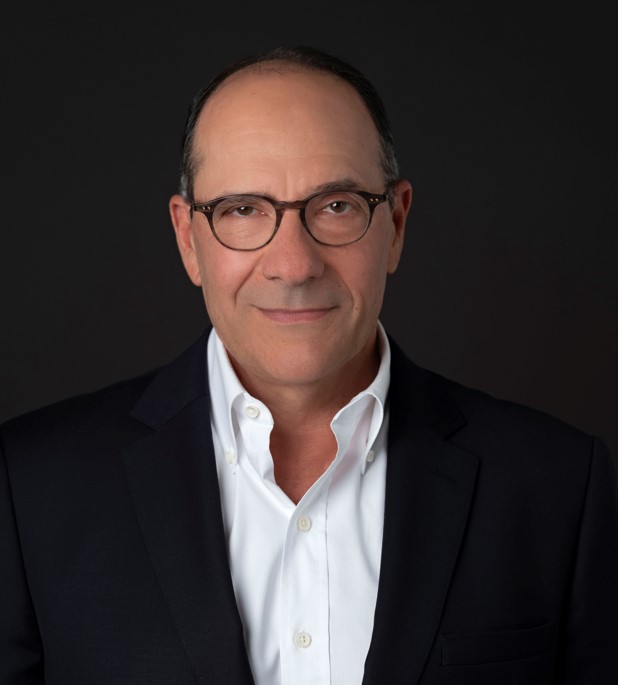

We spoke with Bill Feldberg, Something Inked’s chief marketing officer (and friend of the podcast), about how the company has amassed so many professional sports clients, and how it pulls off the work the playoffs entail.

Promo Marketing: So how did Something Inked first get into the NBA market?

Bill Feldberg: We started originally with the Memphis Grizzlies. And sports is generally a very small niche market. So as people get promoted and move around, one team leads to another team, and so on. As people get promoted and change jobs and stuff, it’s just kind of spiraled from there. But we originally started with doing the Growl Towels for the Memphis Grizzlies. And that was kind of their staple item for a number of years—white T-shirts and yellow or gold towels. And then they went to just doing towels in recent years.

PM: You do more teams now, right?

BF: Yeah, we work with every team in the NBA with the exception of… There’s four teams in the NBA we don’t work with and five teams in the NHL that we don’t work with. But right now we still have the Golden State Warriors in the playoffs and the Boston Bruins. So we have two teams in the finals, one in each sport.

Playoff T-shirts await fans at Oracle Arena ahead of Game 1 of the first-round series between the Warriors and Clippers. pic.twitter.com/HApbJJ7Drr

— Rusty Simmons (@JRustySimmons) April 13, 2019

PM: Was this kind of a snowball effect, where you worked with the Grizzlies and added one team at a time until you were covering virtually the whole league?

BF: It was more gradual. One year we picked up a team, and then another team, and then a couple more. Some years we’ve picked up a bunch. We do kind of a playoff tour towards the spring, where we go around and visit a lot of teams and work with them on their quick-turn needs as they start to project going into the playoffs. And that’s kind of helped with some of our creativity in how to turn very large quantities in a short time.

PM: Obviously all major sports teams do game promos, but it seems like the NBA really embraced the trend of putting T-shirts on every seat before the game to create that atmosphere.

BF: A lot of times it ends up being the games that they know are going to be televised or national games. For sure in the playoffs, every team has gotten to doing the T-shirts on the seats or towels for on the seats. But a lot of times during the regular season it’s the TV games that they know are going to be national televised games that they’ll do it for. Some teams do it pretty regularly regardless, but for the most part it’s the nationally televised stuff that gets the shirts on the seats, because it makes a great pre-game picture and it makes a great in-game story.

TD Garden is looking green for Opening Night. Thanks to @TDBank_US every fan gets a C's t-shirt. pic.twitter.com/HOHkPBUEch

— Boston Celtics (@celtics) October 26, 2016

PM: So right now, with two teams in their respective finals, what is it like behind the scenes for you guys?

BF: Now it’s slowed down quite a bit, because we’re into Game 7 with the NHL playoffs and [the Warriors are in] Game 6 back in Oracle, which would be the last home game in the playoffs for them. It’s slowed down quite a bit for us, but our crazy rounds are the first and second rounds, because you have a significant amount of teams going. I think that this year we had 12 or 14 total teams between both leagues that we were working with on playoff merchandise. It can be rather hectic in the first couple rounds. You have a lot of moving parts. We’re trying to coordinate getting things produced in time for the game [and] getting it delivered. We have print partners that we partner with around the country in order to help cut down on logistics time.

PM: Let’s kind of use that as an example here, those first rounds. What goes into that process from your perspective?

BF: A lot of planning is particularly on the T-shirt side, because you’re looking at 20,000 to 30,000 pieces per game that often have multiple locations on imprint. You have a front imprint. Sometimes you have a front, a back, a sleeve. It just all depends on what the team is wanting to do as far as what their theme is for the playoffs, the sponsors. A lot of variables go into that. So we end up working very closely with our suppliers on making sure that the blank stock is available, making sure that we get it to the city that it needs to be in. We have a logistics company that we’ve set up that handles a lot of our large loads in order to make sure that we can get something printed.

So thrilled to have received my official #NHLBruins Rally Towel from @KechesLaw just in time to be pumped up in my work (in So Cal, as just one of 2 Bruins fans) for #Game7 !!! Thanks, guys!!! pic.twitter.com/odFVZiAHP7

— Tim Wheaton (@TheTimWheaton) June 11, 2019

A lot of times, you’ll know ahead of time when games 1 and 2 are for the home team, so you can start to plan around that. Where it starts to get really tricky is when there’s a game 5 or 6 that’s not guaranteed, and it comes down to depending on if a team might lose game 4 to force a game 5. That’s when you really start to have to put the puzzle together, and [vice president of sales] Todd Schneiderman has become the puppet master, so to speak, of being able to pull the strings behind the scenes in order to get the goods in the right locations and know when to gamble on a team not needing them for the next game, and knowing when they’re absolutely being needed.

I can give you an example. I forget which team it was, but we had our print shop on standby. Everybody in the shop. And then around 9 p.m. when we knew that it was going to be a sweep, we were able to send everyone home and we didn’t have to worry about printing for game 5. Moments like that, where, you know, sometimes it comes down to a matter of minutes. You have the pressers ready, you have the screens burned, and you have everybody waiting to go so that you can get 20,000 shirts printed with multiple imprints in one shift and then get them on a truck the next day so that they can make it to the city to be set on the seats.

PM: Have you ever had a Plan A on standby, and you’re pretty sure you know what’s going to happen, but the game or series shifts and you have to switch to Plan B quickly?

BF: There was a time where I personally jinxed the Brooklyn Nets a while back. It was a couple years ago and Todd never let me forget it. They were up by 12 or something with about 45 seconds to go, and I was like, ‘Oh, cool. We don’t have to worry about it.’ And then they ended up losing that game. But normally we pretty much prepare for all the scenarios. Usually it’s just a matter of whether the shirts need to be printed or not printed. Once the game ends and it’s official, then we know that we can go ahead and start printing. We’ll have everybody on standby, everybody at the shop ready to go. If a team is up by four or five with seconds left, then we can go ahead and start printing.

PM: Working on promotional campaigns like this seems pretty different than a lot of things most distributors are used to. They don’t really have to make these literal game-time decisions or handle variables that are actively happening in front of them, causing them to shift their plans. Am I right about that?

BF: Definitely. But that’s in the playoffs. In the regular season, you have a promotional calendar that you work off of with a team. But during the playoffs, that’s why there’s only a handful of distributors that really work with teams during playoffs, because it’s a completely different animal. It’s a very niche market and very costly in terms of trying to get things done, manpower needed behind the scenes. Especially in that first and second round, most of our team is working 18- or 20-hour days, even just keeping up on emails making sure that trucks are not breaking down. Any time you work with a sports team, you can’t miss a game-day giveaway, but particularly during the playoffs, it really becomes crunch time.

PM: Is there anything else about the process that you’d like to talk about?

BF: I think the T-shirts generally give the greatest television picture, but there are a lot of things that go into it—foam fingers, towels, thunder sticks, a lot of other items that you do in smaller quantities, but the T-shirts and towels tend to be the 20,000 or 30,000 pieces per game. And then they’ll do a lot of smaller items, like an item of a game for foam fingers, or rally sleeves and things like that.