Decoration, as we know, is pretty much the whole focus of the promotional products industry. Sure, the products themselves need to be of high quality, but the decoration is what makes your customers’ logos pop and their brands stand out.

Right now, when so many customers are facing the challenges presented by the pandemic, they are looking for the most bang for their buck. The precious dollars they do have for marketing need to go a long way, so they’re more choosy with the companies they do business with.

You’re already confident in your goods, but how else do you stand out from the competition in the current business climate? You guessed it: decoration.

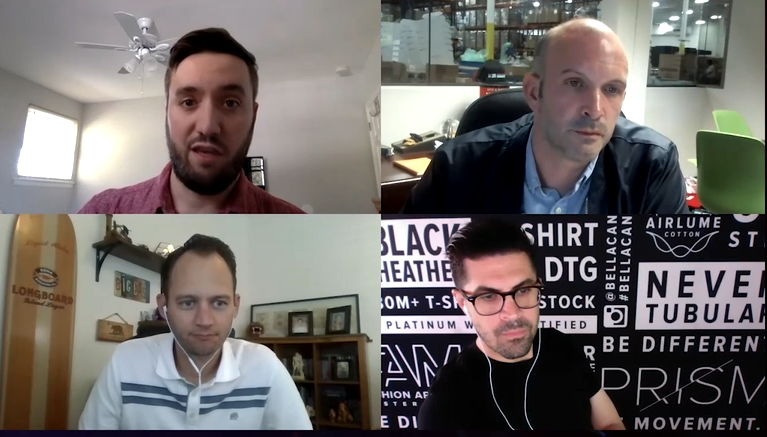

RJ Hagel, manager of global marketing for Goldstar; Tom Davenport, co-founder of Ink Kitchen; and Mike Wilson, vice president of operations for Overture Promotions, joined our own Sean Norris during the PRINTING United Digital Experience for a panel on how promo businesses can take their decoration capabilities to the next level, and how that can attract more business even when times are tough for customers.

“In recent times, people are now looking at this as a long-term effect,” Wilson said. “So, what does that mean? Instead of supplying disposable masks, they want reusable masks, and they want them branded—dye sublimated, screen printed or transferred. We even are seeing regular promotional products coming back, but kind of in a different way. Before, we would have trade shows and we’d be delivering large bulk items to the trade shows. Now we’re coming up with unique ways on virtual trade shows. Whether that means a group of items in a custom kitted box that are going to the [person’s] home, that’s more of what we’re doing.”

When it comes to the decoration processes themselves, Hagel added that things like screen printing and laser engraving, which obviously aren’t new, are still popular. For something like screen printing, the biggest advancement is in the technology that allows things like printing around a curved surface like a pen.

And as full-color printing becomes more commonplace and more advanced, it opens the door for decorators to do more with a product.

“One thing that was great in the recent past was a large financial institution was doing some promotions for Pride Week,” Hagel said. “Because of the full-color decoration, we were able to get a rainbow colored flag around the pen with a message, something that you wouldn’t have been able to achieve on a product like that without going to custom manufacturing, typically overseas, or choosing different colored pens to get that impression, but the person would still walk away with a pen with a single color on it.”

In the apparel space, Davenport said that special effects printing is “making a big comeback,” specifically high density inks, puff inks, transfers, oversized embroidery and appliqué.

For apparel, the look isn’t the only factor to consider. It has to look good, sure, but it also has to feel good. Chunky inks printed on a T-shirt can feel weird, and then that shirt ends up at the bottom of a dresser forever or even in the trash.

“[It has to be] really a nice quality piece, but then also how does that imprint feel and look on the piece?” Wilson said. “Traditional screen printing is basically plastic sitting on top of a garment. That can be heavy. So what other techniques are there out there that we can get better with? Digital printing is definitely one of those, dye sublimation, water-based inks, discharge, different techniques that you can apply to fabric so it’s not so heavy on the garment.”

Davenport added on that idea that apparel decorating needs to feel like a “manufacturing perspective”—you are assembling a finished product.

“Proper ink selection with garment selection is the most important,” he said. “So, when you’re really working with light, soft substrates, the appropriate water-based ink is probably going to be the right way to go, and it’s going to deliver the best finished product.”

To bring things back to the current climate, we can’t overlook the continued importance of masks within the promotional products space. As Wilson said, reusable masks remain strong sellers, and buyers are looking for branded versions. Just like shirts, they still need to feel good when you’re wearing them, and the decoration needs to stand out.

Hagel said that sublimation printing, which used to be an arduous task of setting up a press and heating the design onto the item for 30 or 45 seconds, is now much more efficient thanks to advancements in technology.

“Now you can actually start to do it in large run, and there’s a lot of cut and sew operations, so you can get things like masks and bags and T-shirts, and things that can be decorated on a bolt of fabric at large scale, and then cut to deliver the products one-off,” he said. “It’s pretty impressive.”

If you can properly diversify your decoration capabilities and translate that into other aspects of the role of a distributor, you can stay well above water when times are tough, like right now. In more normal times, you can thrive.

“Screen printing obviously led to embroidery, and to heat pressing, etc.,” Davenport said. “Decoration led to packaging. Packaging led to fulfillment, distribution. I really kind of built my business that way. In tough times I actually saved my business on that convergence of technologies on our production floor.”

Click here to view the entire session (free registration required) or click here for more information on the PRINTING United Digital Experience, including recorded versions of each day’s education sessions and product demos. The PRINTING United Digital Experience runs from Oct. 26 through Nov. 12 and is free to attend.