In 1946, Malcolm P. “Mack” Niven founded Greenville, South Carolina-based Carolina Manufacturing—home to the Hav-A-Hank handkerchief—which has since become the leading bandanna manufacturer in the U.S. Its American roots are still strong 75 years later as it continues to sell its bandanna lines, such as Hav-A-Hank, in retail outlets, and its logo-friendly designs through promotional product distributors.

“Having decades of USA-made production in the promotional industry has helped tremendously in navigating the challenges 2021 brought,” said Scott Thackston, director of marketing and product development at Bandanna Promotions by Caro-Line. “We are proud to have met our in-hands dates by keeping full inventory levels with real-time production for our distributor partners, allowing their client’s orders to be produced seamlessly.”

Strength in Roots

“Bandanna Promotions has evolved over its 75-year existence, but one thing has always remained consistent—its status as an American-made business,” said Pam Scott, national sales director at Bandanna Promotions by Caro-Line, the promotional division of Carolina Manufacturing. “Our original 22-inch bandannas have remained the same, but we have developed our line to include more unique styles, sizes and colors, as well as an array of other wearable fabric accessories.”

Bandanna Promotions entered the promotional products scene in 1985 when then-owner Fendrich Industries—which purchased the company in 1963—joined industry associations. A year later, Fendrich acquired Carolina Yarn Processors, an 86,000-square-foot facility in Tryon, North Carolina, that dyes and finishes cotton and synthetic yarns for high-end home furnishing weavers and its sister manufacturing company. In 1996, he developed a 39,000-square-foot facility in Union, South Carolina, to house Union County Printworks in order to serve the quick turnaround time and printing needs the promo industry demanded.

The printing arm of the company is responsible for bleaching and preparing greige goods that are then sent to the Greenville, South Carolina, turnkey production facility in 750-yard rolls of cloth that measure 45” wide. It’s there that orders are cut, sewn, printed and fulfilled. From Hav-a-Hank and the original paisley bandanna to newer products like Pick-a-Pillow and Fashion-Danna, Bandanna Promotions continues its growth as it moves into 2022 while strengthening and maintaining its roots in custom textile USA production. Learn how bandannas are printed via rotary, duplex, silkscreen and digital options in the nation’s only four imprint processes operation.

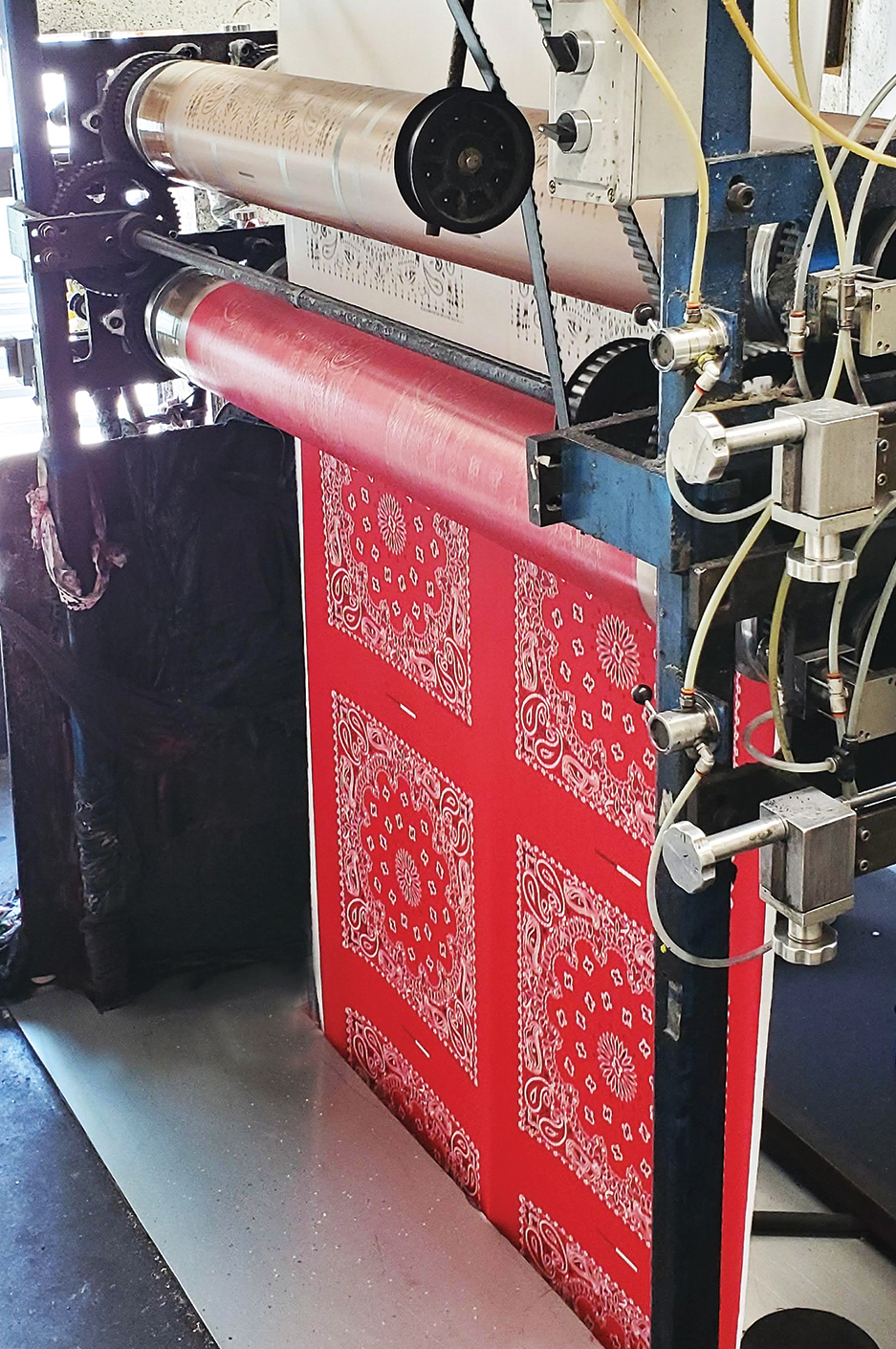

Rotary

Rotary printing is a great option for larger runs. It uses eco-friendly, water-based pigment dyes that absorb into the white cloth and create a softer bandanna. The white rolls run through the rotary machine where up to eight colors can be printed. The result is truer colors and optimal PMS matches. Printed pieces are then cut and sewn domestically. This method, which has a 2,500-piece minimum, also offers more ink colors, faster production and a lower price than its screen-print counterpart.

Rotary is available on 22” bandannas, small and large pet triangles, 14” hankies, Table-Dannas, Fashion-Dannas and more.

Duplex

For paisley printing, Bandanna Promotions previously outsourced work to other U.S. companies that did dye and discharge printing for these designs. When its partners’ production moved overseas, Fendrich stuck to its American-made focus and invested in a custom-made duplex machine to keep the company’s printing stateside.

While different from rotary printing, duplex printing still achieves the same result—a two-sided print as opposed to a mirrored image on the back. This proprietary print method is now also used for custom prints and is exclusive to Bandanna Promotions within the promo industry. It requires a 10,000-piece minimum and two-color maximum design.

Like rotary, duplex is also printed onto white fabric rolls before being cut and sewn in Greenville, South Carolina. It is also available on 22” bandannas and large pet triangles.

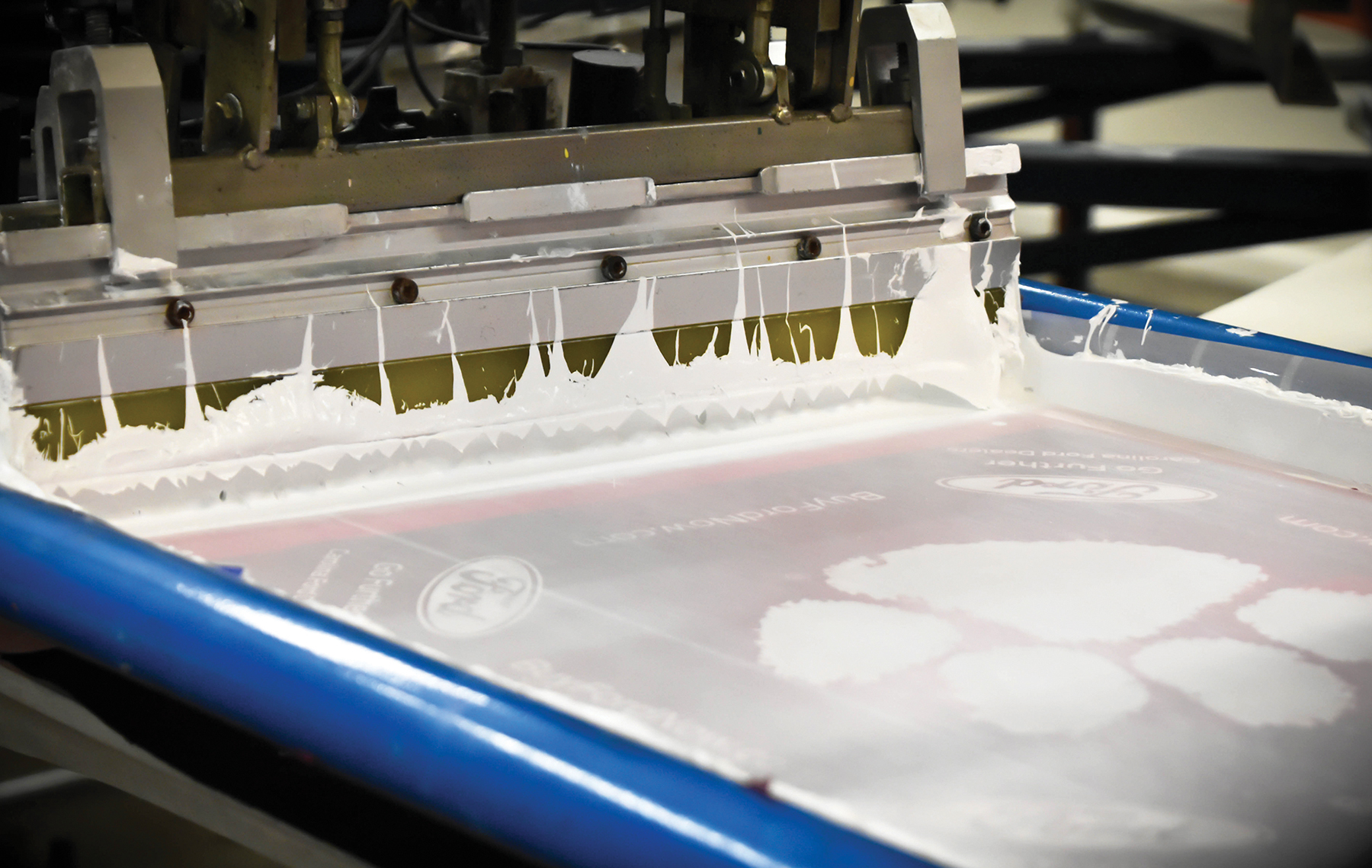

Silkscreen

Smaller runs of at least 144 pieces are best served by screen printing, though it can accommodate larger order sizes, as well. The fabric is dyed and then cut and sewn into blanks at its manufacturing facility. The blanks are then ready for this one-sided imprint with up to six spot colors. Unlike rotary, the ink rests on top of the fabric and, therefore, can be felt. In addition to maintaining a vast inventory of USA-made bandannas, Bandanna Promotions also imports certain blank styles in select colors for very competitive bid situations, providing options in a world that’s currently experiencing supply shortages.

Silkscreen is available on 22” and 27” bandannas; small, large, and extra-large triangles; and 14” hankies.

Digital

Digital runs on a large-format, flatbed inkjet printer, providing 100% custom, edge-to-edge designs printed on white cloth. This method can replicate detailed custom designs, including photographs, for added impact. It supports low minimums, unlimited color options, and no screen or setup fees.

Products offered with digital prints include Digi-Danna, Digi-Triangle, Gaiter Sleeve and more. Choose among three fabrics: 100% cotton, 100% fine sateen cotton and 100% peachskin polyester.

“We are proud to be an American manufacturer,” Scott said. “Our owner could have followed other textile mills overseas, but he chose to keep the business right here in the Carolinas. Being stateside offers a lot of perks for our customers. When playoff and championship game results aren’t final until the last out or final seconds of a game, we can wait until the score is final to produce and ship a large number of Wave-A-Hankies and Spirit-Dannas. We cherish being able to meet our clients’ needs in ways we wouldn’t be able to do if we relied on overseas manufacturers.”

Added Thackston: “As we move forward into 2022 with full momentum on the industry’s recovery, it’s a wonderful time to see how USA manufacturing is growing to new heights in making this happen with Bandanna Promotions by Caro-Line leading the way.”