Key Takeaways:

• Emerging Technologies in Decoration: Direct-to-Film (DTF), UV DTF, Hybrid Printing, and Dye Sublimation each offer unique advantages and challenges for the promotional products industry.

• Pros and Cons of Each Method: Each decoration method has its own set of pros and cons. For example, DTF is versatile and easy to learn but may not be ideal for bulk prints.

• Integrated Services: Integrating promo decoration and distribution services can enhance marketing strategies, providing a comprehensive solution for clients and improving the overall impact of promotional campaigns.

Tried-and-true decoration techniques, like embroidery and screen printing, are still alive and kicking, but it’s worth looking at some of the other trending methods being leveraged in the promotional products industry. Here’s a rundown of four technologies to watch, along with the pros and cons of each.

Direct-to-Film (DTF)

In the last few years, perhaps no other decoration technique has been more talked about than direct-to-film (DTF) transfers. “DTF is a disruptive technology,” says Jay Busselle, a decorating industry veteran and founder of FLEXpoint Social Selling. “It’s emerging, and it’s exploding.” The technology has followed a similar trajectory to the direct-to-garment (DTG) boom of the early 2000s, albeit at a much more frenetic pace.

With DTF, decorators use an inkjet printer to print onto special transfer film, then apply a powder adhesive to the wet ink. The powdered design is then passed under a heat press to cure. Once cured, the design can be transferred to a substrate, using a heat press to melt the adhesive and bond it to the fabric. After pressing, the film is peeled away – leaving a vibrant print.

Pros: With DTF, decorators can add vibrant, detailed images to a variety of fabrics and locations. “It’s substrate agnostic,” according to Jed Seifert, owner of Stakes Manufacturing (asi/88974), an Eastlake, OH-based large-scale print-on-demand decorator. “This is really a game-changer because of all the different things you can decorate that you just couldn’t do with DTG.” There’s also a lower barrier to entry, compared to many other decorating techniques, and the technology is relatively simple to learn.

Cons: DTF prints typically have a “plasticky” hand feel, so a big blocky print across the front of a T-shirt is likely to be unappealing. For bulk print runs, DTF is probably not the best choice. For one- or two-color orders in large quantities, traditional screen printing is still probably the better option.

UV DTF

For hard goods, UV DTF printing has become a popular choice, enabling decorators to create durable, full-color, peel-and-stick decals by printing designs onto a film using UV-curable inks. Most machines automatically send the film through a built-in self-laminator, enhancing the look and durability. Unlike with traditional UV digital printing, UV DTF enables decorators to decorate on curved surfaces.

“UV DTF printing allows you to print high-contrast designs on nearly any nonporous surface, including glass, plastics, metal and more – perfect if your shop offers awards or other promo products,” says Brian Belk, managing director at Axiom America, parent company of Arcus Printers, which offers an array of digital printing equipment and supplies.

Pros: UV DTF transfers are pressure-applied, and don’t require a heat application like other transfers, making them excellent for a variety of hard goods. They’re also durable, scratch-resistant and don’t fade over time when exposed to sunlight and harsh weather.

Cons: UV DTF printing involves more steps than traditional UV printing, making it less efficient for larger order sizes. Plus, as a relatively new product, UV DTF can carry a higher price tag than other equivalent decoration methods.

Hybrid Printing

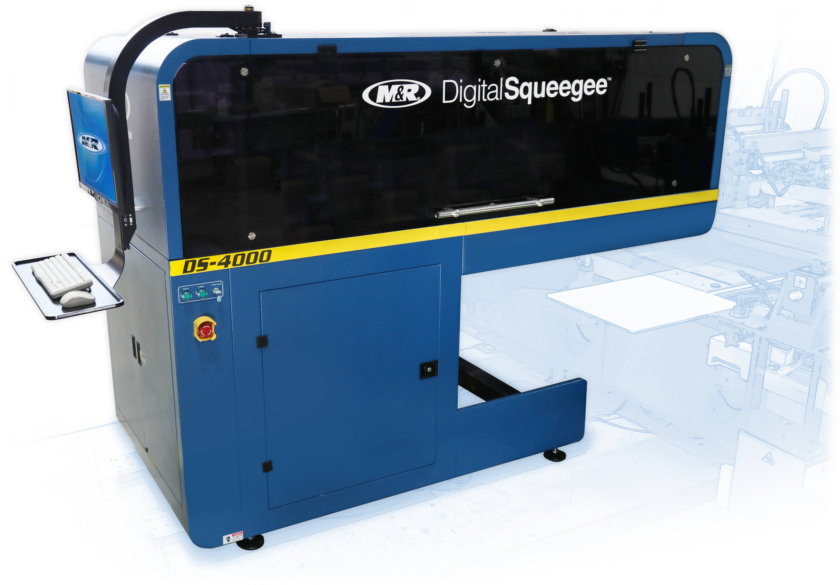

This decoration method is a combination of traditional screen printing with digital DTG printing. Essentially, the machine lays down a screen-printed white underbase on a garment, which then rotates to a digital printhead, which can print a high-resolution full-color design on the base. M&R, an equipment manufacturer that makes a Digital Squeegee hybrid printer, notes on its website that its machine saves time and effort on small and midsize print runs. The screen-printed underbase eliminates the need for a pretreatment step usually required for DTG printing, and incorporating digital printing enables detailed, vibrant designs without all the setup.

Pros: Hybrid printing is a great choice for printers looking to do high-color jobs, without all of the pre-production labor involved in traditional screen printing. Incorporating a screen-printed white underbase also saves on costs, compared to digital white underbase inks. Plus, the ability to print variable data in the same print run adds versatility.

Cons: These machines typically have a high upfront investment and need ample shop square footage, since they require setting up a large automatic screen-printing press. Plus, the equipment tends to have high operational and maintenance costs.

Dye Sublimation

Dye-sublimation printing is a useful decoration method, both for apparel and hard goods, as long as they’re made of polyester-based materials for apparel or coated with a particular polymer for hard goods. The sublimation process involves printing an image on special paper, which is then transferred onto a substrate using a heat press. Unlike with other heat transfers, which sit on the surface of a substrate after being pressed, sublimation dyes transform from a solid to a gas, bonding with the material to create a permanent image.

With the right heat press and attachments, decorators can sublimate an array of promo products – from mugs and tumblers to blankets, towels, flags and banners. Other possibilities include name badges, plaques, pens, lip balms and can coolers. One key to remember, however, is that the process is most effective on white or light-colored items.

Pros: Dye sublimation allows for high-quality, full-coverage, durable prints on a variety of hard and soft goods. Designs can be vibrant and intricate and are resistant to cracking, peeling and fading, since the inks are bonded to the substrate during the decoration process.

Cons: The process isn’t suited for natural fabrics like cotton and works best with white or light-colored substrates, which can be limiting.

Case Study: How This Marketing Agency Leverages Wide-Format Printing & Promo Decoration

For printers looking to offer one-stop shop services, expanding into promo decoration and distribution is a win-win. Take Phase 3 Marketing & Communications (asi/290433), an Atlanta-based integrated marketing services firm, which incorporated branded merch into its menu of services seven years ago through acquisition. The distributor also has several printing facilities, with digital presses, for printing marketing collateral. And it offers in-house screen printing and embroidery services.

Adding promo, says Meredith Schwarz, VP of sales, has allowed the company to offer a full-service solution to customers working on things like product launches and experiential marketing pieces. The process, Schwarz says, typically begins by building a creative strategy and then moves into the physical pieces that need to be fabricated and printed. “It’s always the big pieces – like building a pop-up shop – that come first,” she says. “The idea of giving something away is almost always at the very end of the thought path.”

Having promo services in-house helps to bring that conversation to the beginning of the process, ensuring the inclusion of thoughtful, high-impact branded merch. Phase 3 showed how seamlessly promo and printing work together when it participated in the recent StorePoint Fashion Expo, creating an in-store fashion display experience with the theme of “Around the World in 8 Displays.” The booth showcased large-format print and custom-fabricated retail displays. To make it more memorable, Phase 3 offered P3-branded snacks, a printed passport and a travel kit takeaway gift.

By providing promo products, Phase 3 is able to execute what the client has in mind more fully, Schwarz says. “We’re able to offer a more complete thought.”