Key Takeaways

• The shift to print on demand, combined with e-commerce, allows for faster delivery, customization, and sustainability—meeting the needs of consumers who expect convenience and choice.

• Distributors must manage both the “front of house” (e-commerce platforms) and “back of house” (production processes), ensuring proper equipment, garment-specific print settings, and scalable systems.

• Limited-time pop-up stores and integrated platforms like ESP+ Stores help distributors drive demand, reduce risk, and tap into recurring revenue streams as e-commerce adoption accelerates.

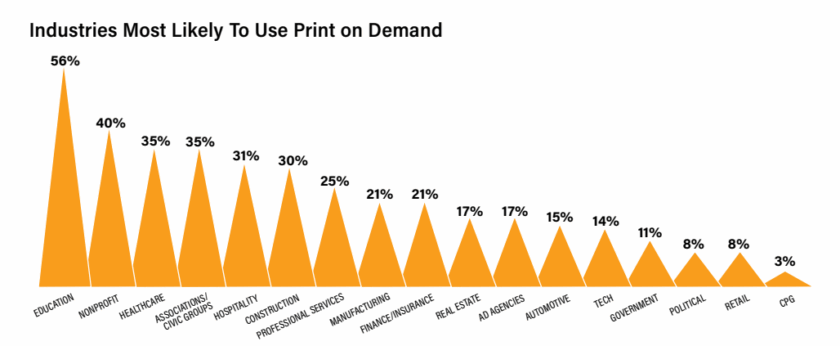

The print-on-demand revolution is here. Simply put, the way promotional products and branded merchandise are decorated and delivered has changed. You don’t have to print products in bulk, nor are giveaways tied to being physically present at an event. The numbers back up this claim: ASI Research found that 54% of distributors offer print-on-demand services to clients.

It’s a change welcomed by a buying class raised in the internet age who want products right now. They’re used to purchasing items conveniently from their own home or on their phone, and having them delivered quickly – even the same day. (Bonus points too if the things they order are sustainably sourced.)

Meanwhile, advancements like direct-to-film and direct-to-garment decoration have made it so distributors and printers (and those who are just dipping their toes into this space) can print as many products as there is demand for – no worry about piles of boxes sitting in a garage forever.

Print on demand and the boom of e-commerce go hand in hand – dual innovations that meet the needs of current buyers. Programs are put in place so people can order the exact product they want from an online platform rather than simply receiving a one-product-fits-all solution in person. Companies are giving their employees ways to be rewarded for their effort through branded sites.

Behind the scenes, printing on demand often pushes the whole program forward. And there’s a growing group of industry evangelists who believe this is the future.

Jayson Tompkins, chief digital officer at Stahls’ (asi/88984) and founder of Stahls’ Fulfill Engine, has built his career out of helping end-buyers like schools and nonprofits with their branded merchandise at his company Print Your Cause, which he then continued into the corporate world with corporate giving programs – all of this built on print on demand. Tompkins eventually founded Fulfill Engine, which was acquired by Stahls’ and integrated as the Fulfill Engine platform the company now uses.

For Tompkins, the pandemic was a catalyst that maybe sped up the adoption of print on demand and e-commerce, but it was a trend that was coming sooner or later even without the kick start.

“COVID accelerated the way we look at print on demand,” Tompkins says. “Very early on it was just a very frustrating consumer experience to have to wait on decoration to be done in bulk. It’s frustrating for the person who’s in, say, HR or marketing that wants to get swag to their employees to pick one-size-fits-all-type items, or have to be limited in terms of what they can do because they need to take an inventory position or need to collect orders. So on-demand not only helps with things like sustainability but also being able to pivot into different styles and products.”

Tompkins is one of those who believes in the model of print on demand tied in with e-commerce platforms – where end-recipients can pick and choose tailor-made products rather than distributors and brands trying their luck casting a wide net. To that point, he believes that the desire for premium products will continue to rise, and print on demand and e-commerce will complement that need.

“Choice, sustainability, speed,” he says. “It all aligns with on-demand.”

Adopting Print on Demand

For printers and distributors, as well as those just getting into the branded merchandise industry, who are interested in potentially doing print on demand with e-commerce, it’s smart to think of the two sides as complementary but separate. Consider a restaurant that has the front of house (where food and drinks are served and the staff interacts with the guests) and the back of house (where the food is stored and prepared). The front of house would be the e-commerce platform that the end-user ultimately uses, and the back of house would be the actual work of printing and decorating the products.

We’ll focus on the “back” first.

Jed Seifert, co-founder of Stakes Manufacturing (asi/88974), is a part of a huge print-on-demand enterprise that services clients in the B2B space all over the country. Stakes works with clients in the consumer brands, entertainment, sports teams and education markets, all through e-commerce platforms with more than 110,000 SKUs.

Of course, it’s crucial to know what decoration techniques and equipment you’re going to employ, but Seifert says you have to know first who your clientele is.

“Before you figure out the equipment you’re going to use, you need to figure out the niches that you’re going to be servicing,” he says. “That will help formulate your decisions on what equipment you’re going to use.”

He points to the sports market. For example, he says, if you’re working on shirts for a local Little League or high school team, your operation can be congruent with that, meaning that you probably don’t need the highest of high-tech production equipment or pricey tech investments. By comparison, if you’re working with a big college or professional team, you might need to look into more precise capabilities like Pantone matching and higher-volume printers.

Decorators using digital printers too should be wary of how different substrates react to the printing process.

“From the production standpoint, you’re going to have to make sure that you’re creating all of your recipes for how you’re going to print every garment, because all the garments print differently digitally,” Seifert says. “It’s not as simple as screen print or embroidery where it’s pretty standard from garment to garment. Every garment is going to print differently and require different settings in order to maximize quality and durability.”

Managing the Front of House

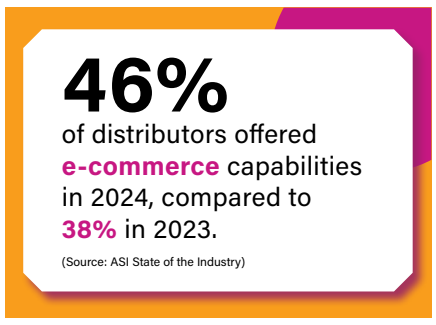

It was nearly 30 years ago that e-commerce ordering of promo products first started to take off. Three decades later, the options for distributors have grown incredibly robust and varied.

Grace Schettler, senior vice president of sales for Chipply, says that she’s noticed a decrease in the number of traditional fulfillment houses in the industry. But while the automation process and “on-demand” functionality is growing, it’s often still not a completely hands-off process for printers and distributors.

“The disadvantage of the way it works today is that you still have to go in and touch each order,” she says. “There are things that are coming down the pipeline to make that easier, because if you do have 200 stores open, to go into 200 stores when you have 200 orders and touch every order is too time-consuming for the return on print on demand.”

Schettler also has noticed a lot of success in limited-time pop-up stores. This can be a way for companies to drive demand for products using scarcity. Think about a streetwear drop or a seasonal release where buyers have to “act now!”

This could be a way to combine housing stock in limited quantities while maintaining a less risky print-on-demand business with basics that are easy to acquire from wholesale suppliers and print quickly.

“The store’s open for two weeks, and I’d better order these goods because they’re not going to be there anymore,” she says. “It’s the same thing you’d see as a consumer. There’s a special color of suitcases out, and I’d better order this color today or it’s going to be gone. We do that same sort of thing in web stores because it’s still a decorated product.” She cites the example of specialty items (such as a women’s cowl-neck top or sherpa jacket) that are harder to get from a wholesaler compared to basics such as tees and hoodies.

Kevin Oakley, co-founder and chief revenue officer for MerchLoop, says that once the system is set up, you can scale the print-on-demand and e-commerce wings of the business to larger clients. For him and MerchLoop, it meant growing from the smaller creator economy to gearing their business capabilities toward more corporate customers who want to turn their web store into an on-demand-backed store.

They’ve also managed to balance the on-demand model with the traditional inventory model and have even found ways to integrate another customer’s dead stock, showing the two ways of selling can coexist and even complement one another.

“We don’t shy away from the bulk side of the business, because that is a pretty decent size of our business on the screen-printing and embroidery and promo sides,” he says. “We do understand warehousing as well. What generally happens is, if they’re working with another company, they’ll send us the leftovers of their existing inventory and we’ll run that out and transition everything over to an on-demand model.”

For Smaller Companies

Seifert says that while print on demand hasn’t fully taken over the industry, he sees it to some degree at a lot of companies. The larger firms, he says, are a mix of traditional inventorying and print on demand, but a lot of the smaller companies are choosing print on demand to minimize risk.

Leverage Powerful E-Commerce With ESP+ Stores

Counselor’s 2025 State of the Industry report found that 48% of distributors offer company stores – a figure that has increased each of the last two years. So as e-commerce continues to thrive and fuel print on demand, company stores will be an increasingly important part of the equation.

To that end, ASI’s ESP+ Stores is a fully integrated, end-to-end e-commerce solution that empowers distributors to quickly create and manage custom-branded online stores for their clients. Built directly into the ESP+ ecosystem, the platform eliminates the complexity of third-party tools and offers a seamless workflow from product selection to order fulfillment. With unmatched product data accuracy, streamlined logistics and marketing tools built in, ESP+ Stores helps distributors boost efficiency, increase retention and grow revenue – all in one place.

ESP+ Stores is optimized for distributors with recurring or high-volume clients, corporate program managers, and sales and marketing directors at distributor companies. It alleviates pain points like the time-consuming manual order process, disconnected systems and inconsistent product updates, and difficulty offering scalable and customized e-commerce solutions to clients.

With just five simple steps, promo distributors can set up their store and get it running without any web development knowledge necessary. The custom store can be personalized with logos, brand colors and themes, and reflect the client’s identity to deliver a premium shopping experience. ESP+ Stores provides built-in features to promote store launches and special offers, convert existing client presentations into stores, combine orders into single purchase orders per supplier to cut down on logistics complexity and reduce shipping costs, and reflect product availability with real-time ESP product database integration.

Visit asicentral.com/distributors/product-marketplace/ to learn more.

“You’re trying to only buy what you know you’re selling,” Oakley says. “You’re trying to make sure that every design you launch is a winner. It’s difficult, because some things you just can’t control. You can’t control that all of a sudden a color that was trending – it might not even be just the garment – the color that was trending is no longer trending, or the design that was popping off consistently all of a sudden fizzles out, and you’re sitting there with all of that inventory and closing the door on the other products and designs you could be launching.”

Oakley says that, for now, while print on demand is certainly making ripples, it isn’t the death knell for the traditional means of selling promo, due in part to the investment it requires.

“I think the biggest hurdle that most distributors will face is just the tech stack and the actual fulfillment of this,” he says. “You have to have really good tech and then fulfill in-house or have a partner that can allow you to make the same margins that you’re making when you’re doing bulk as well.”