If 2020 was the year of staying indoors and taking a break from live events, 2021 has been the year of resurgence, with more people getting back into the social life. With events such as concerts, running and bike races, and even corporate get-togethers getting back to full swing (in safe fashion, of course), people are not only looking for swag to commemorate their first event post-global shutdown, but they are also looking for something custom and cool.

“Since March, events have come back in a flurry with a peak in outdoor concerts, festivals and sporting events late summer through the fall,” says Scott Thackston, director of marketing & product development at Bandanna Promotions by Caro-Line.

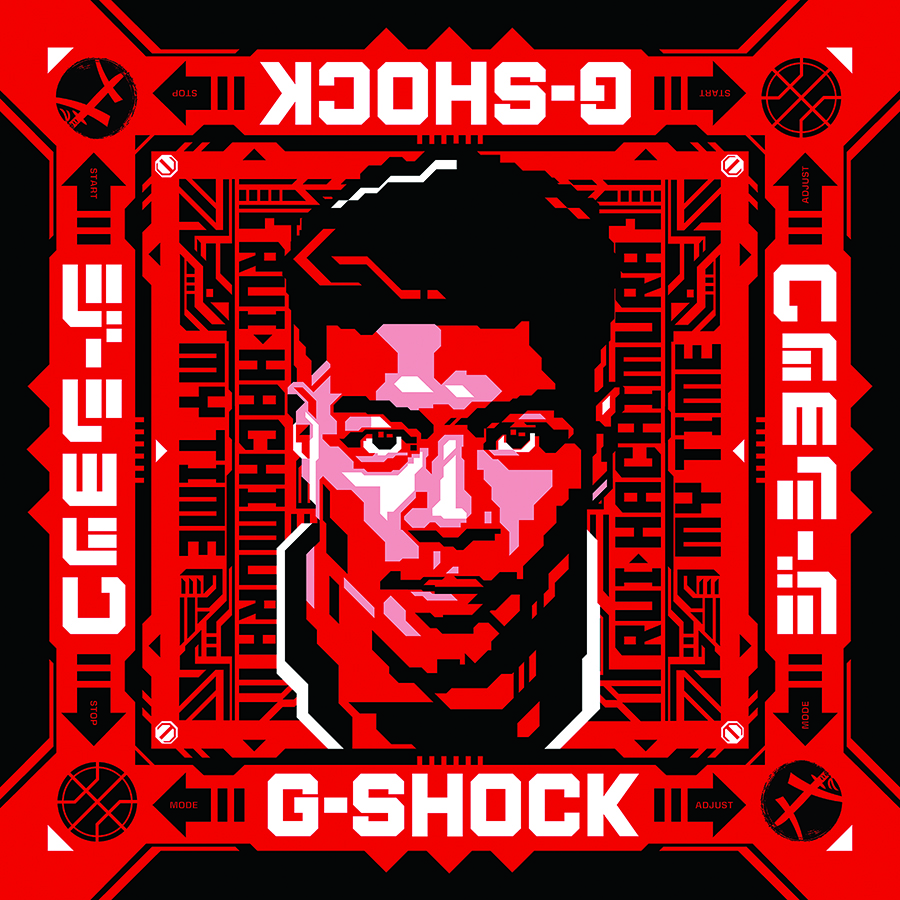

If you’re looking to add a custom touch to your customer’s next promotion, rotary-printed bandannas—available from Bandanna Promotions by Caro-Line—fit the bill. “With custom color bandanna options, it opens the color wheel of seasonal, themes, or corporate logo colors to fit any event with the powerful logo branding [and] pop plus the splash of color needed to make any event fun with this functional wearable giveaway,” said Thackston. USA-made with a fast turnaround, and edge-to-edge printing depending on the desired design, you can’t go wrong pitching this bandanna.

Why Go With Rotary Printing?

Rotary screen printing offers a lot of benefits, but it helps to understand both the process and why it is best for a particular order. Let’s start with order numbers. If you’re looking to keep your order around 2,500-plus pieces or so, you can choose between silkscreen or rotary to print your bandannas. Silkscreen is your least-expensive option when ordering between 144 to 2,000 pieces. Silkscreen is a one-sided topical surface imprint on cloth that has been dyed a color and cut and sewn into bandannas.

However, once your order hits that 2,500 count, rotary is the way to go. “As the quantity increases rotary offers faster production time, better pricing, and more design color options,” notes Thackston. Starting at 2,500 pieces, Bandanna Promotions can use the rotary print process to print up to eight colors depending on the job with only a few minor restrictions. Plus, edge-to-edge printing is also a possibility with rotary printing; just keep in mind that only certain layouts will work. If your design can’t be printed edge-to-edge, the imprint or logo area is 19”x19″ with base color bleeds as full coverage to edges.

The hand or feel of the bandanna should also be considered. With silkscreen imprints, the ink sits on top of the fabric and can be felt when you rub your hand over it. Rotary printing creates a softer bandanna because the eco-friendly, water-based pigment dyes—which don’t contain harmful chemicals—are absorbed into the cloth. As a result, the print cannot be felt when you rub your hand over it, becoming part of the material.

Rotary printing starts with 100% cotton or 50/50% polycotton white cloth. And if you’re concerned about color, that’s another benefit to the process. Each color in your client’s design is printed directly on white cloth, which is the base color, making colors vibrant and true. PMS colors can also be easily matched.

Rotary screen printing uses precision-cut stencils, or screens, to create an image. Multiple screens can be used to create a multi-color design. The design is applied as the fabric moves through the machine, which allows for large quantities of goods to be produced. “With no screen or setup charges, [we offer] a faster turnaround than any other supplier and edge-to-edge printing with select designs,” said Thackston.

Production speeds of rotary screen presses do vary based on the complexity of the design, the type of material, and the ink or chemistry used. While full-color designs can’t be printed with rotary, your clients can still get a similar look using halftones and gradient blends. This requires printing your client’s design in five to eight colors (depending on quantity ordered).

Target Markets

Another major benefit to this process being used to print bandannas is the wide appeal and final look that can be achieved. Not only can you get a unique look with the bandannas that your customers are sure to love, but they also work across a huge selection of markets.

“Your design is printed on one side of the bandanna, with colors being pushed through the fabric with dye penetration,” said Thackston. “This creates a two-sided illusion as a complete bandanna side look of the color and design on the back, which is more noticeable and gives a faux two-sided bandanna print.” With silkscreen, because the cloth has been dyed, it is the same color front and back.

A unique look deserves to be marketed—here are a few ideas on customers you can target and sell these bandannas to:

- Races and Charity Events (think 5ks, marathons, and bike events)

- Hospitals and Healthcare

- Festivals and Concerts

- Pet Market

- Beverage and Sports

This is just the beginning. “Bandannas are one of the most versatile textile promotional products in the industry,” said Thackston. “They make a fashion statement, are functional outdoor accessories, and are also favorites with pet owners, too, as dog triangles.” In addition to that, distributors can also offer them to fitness and sports groups as well as schools. It seems that the possibilities are endless.

Beyond these markets, there are also unique uses for custom color bandannas to capitalize on. For instance, they make great invitations for personal and corporate events. “Color matching for top brands and corporate logos are a must for advertising identity,” emphasizes Thackston, circling back to the ease with which colors can be matched with the rotary process.

You can even go a little further with the color conversation. “With custom color backgrounds, you can take that one step further with all shades of pink, blues, etc., for cause awareness and charities, and medical identification,” Thackston notes.

But, as previously mentioned, target customers are really just about anybody. “Sell this style to clients looking for more colors, faster USA production, or a softer-feeling bandanna printed with eco-friendly water-based pigment dyes,” Thackston said.