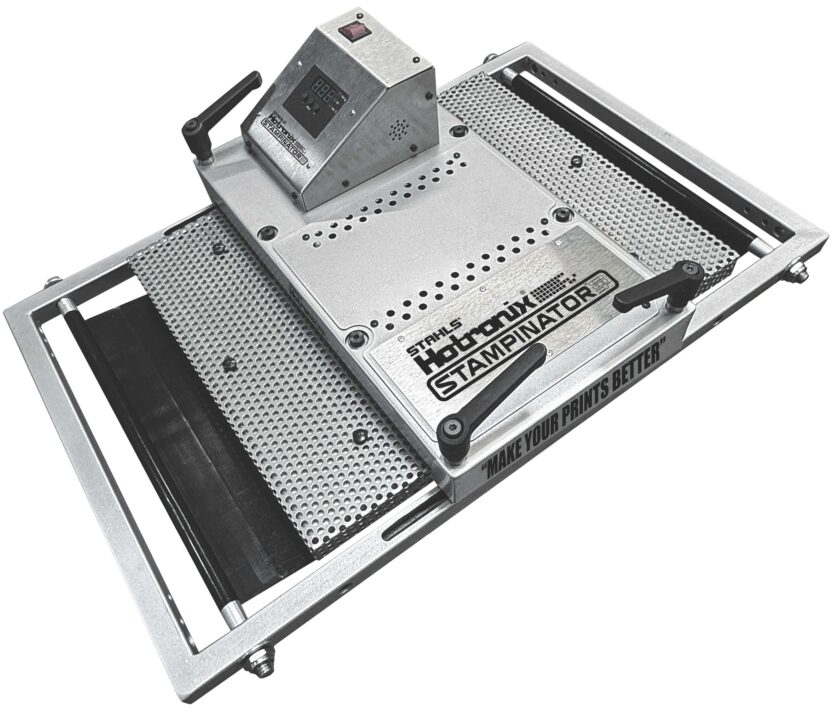

STAHLS’ (asi/88984) has announced that it has formed a manufacturing, distribution and service agreement between its Hotronix heat press division and Stampinator, bringing heat press technology to decorators with automatic screen-printing technology using Stampinator products.

According to a release from STAHLS’, the partnership blends the capabilities of Hotronix IQ heat press and Stampinator’s goal of adding new printing methods to automatic screen printers like DTF and heat transfer.

The companies said that the Hotronix IQ partnership will allow printers to achieve underbase stamping to smooth the fibers of the product and achieve quick curing, better imprint opacity and noticeably brighter transfers on a variety of fabrics.

“This partnership combines Hotronix’s heat press expertise with Stampinator’s innovative screen-print press conversion concept,” said STAHLS’ CEO Carleen Gray, a member of Counselor’s Power 50 list of promo’s most influential people. “We’re very proud to help deliver technology that allows screen printers to scale and offer premium results with every job.”

automatic screen-printing equipment

The Stampinator innovation allows heat transfer to complement screen printing and vice versa, added STAHLS’ Chief Revenue Officer Josh Ellsworth. “With demand for new fabrics, full-color graphics and shorter run sizes, it is an addition certain to bring an immediate benefit to every shop,” Ellsworth said.

Now with the Hotronix heat press technology on Stampinator presses, decorators can add finishes like foil and rhinestones, as well as screen printing with heat transfer vinyl and specialty CAD-CUT finishes.

“The Stampinator brand is built by screen printers for screen printers,” said Stampinator Founder and President Jeff Fiorucci. “Our call to action is ‘Make your printers better.’ We are excited to take the Stampinator to the next level with the precision of Hotronix technology, including international distribution and future adaptations.”